Zingaki izinhlobo zokwelashwa kokushisa kwe-anneal ozaziyo?

I-Annealing iyinqubo yokwelapha ukushisa lapho insimbi nama-alloys kushiselwa khona ezingeni lokushisa elifanele isikhathi esithile bese likuvumela ukuthi liphole kancane (ukupholisa kwesithando somlilo). Inhloso ye-annealing ukuguqula insimbi isuka ku-Austenite iye ku-Pearlite, ukunciphisa ubulukhuni nokwandisa i-ductility, ukwenza kube lula ukuguqulwa kwemishini nokubandayo, futhi ngesikhathi esifanayo iyunifomu yokwakheka kwamakhemikhali kanye nesakhiwo sensimbi ukuqeda ukucindezeleka kwangaphakathi nokusebenza ukuqina, ukuvimbela ukuguquguquka nokuqhekeka. . Ezinye izinhlobo ze-Aluminium, Ithusi, titanium nezinye izinto ezisetshenziswayo zingase futhi ziphendule inqubo yokukhishwa kwesisu. Izindlela ezijwayelekile zokukhipha isisu ngokuya ngezinga lokushisa kanye nokwakheka kwamakhemikhali enqubeni, i-annealing ingahlukaniswa ibe:

1.Ukugcwalisa Okugcwele.

Shisisa insimbi ibe ngu-20 ~ 30 ℃ futhi ugcine isikhathi ngemva kokupholisa kancane ukuze usondele ekulinganiseni inqubo yokwelapha ukushisa yenhlangano (i-austenitizing ngokuphelele). I-annealing egcwele isetshenziselwa ikakhulukazi amashidi Asetshenziselwe Okushisayo, ama-forging, nama-castings okwenziwa ngezinsimbi zekhabhoni ezimaphakathi neziphezulu kanye nezingxenye zayo zokushisela. Ukuqina kwensimbi ye-carbon steel ngemuva kokudonsa akulungile ekwenzeni imishini.

I-annealing egcwele ihloselwe ukucwenga okusanhlamvu, isakhiwo se-homogeneous, ukuqeda ukucindezeleka kwangaphakathi, ukunciphisa ubulukhuni nokuthuthukisa ukusebenza kwensimbi. Ngemva kokufakwa ngokugcwele, ukwakheka kwensimbi ye-hypoeutectoid ngu-F+P. Emkhiqizweni wangempela, ukuze kuthuthukiswe ukukhiqiza, ukupholisa kwe-anneal kuze kufike ku-500℃ noma khipha amakhaza.

2. Ukufakwa Okuyingxenye.

Shisisa insimbi esimweni sensimbi ye-hypoeutectoid noma i-hypereutectoid bese upholisa kancane ngemva kokugcina ukushisa ukuze uthole inqubo yokwelapha ukushisa eduze nesakhiwo esinokulinganisela. Isetshenziselwa ikakhulukazi ukuthola isakhiwo se-pearlite esiyindilinga ukuqeda ukucindezeleka kwangaphakathi, ukunciphisa ubulukhuni nokuthuthukisa ukusebenza kwemishini. I-Spheroidization annealing iwuhlobo lokudonsa kancane.

3. I-Isothermal Annealing.

Le nqubo ibizwa nangokuthi i-grecrystallization annealing lapho insimbi ishiselwa ekushiseni okuphakeme kunokushisa okubucayi, ihlala isikhathi eside futhi iphole ngokushesha ekushiseni kwegumbi, okwenza uguquko lusuka e-Austenite luye ePearlite. Kuthatha isikhathi eside ukuqeda ukuthungatha okugcwele, ikakhulukazi izinsimbi ezingenasici ze-Austenitic ezipholile kakhulu, kuyilapho ukudonsa kwe-isothermal kungafinyeza kakhulu isikhathi sokukhipha.

Le nqubo ingeyensimbi ephezulu ye-carbon (C> 0.6%), insimbi yethuluzi, insimbi ye-alloy (inani le-alloy element> 10%). I-Isothermal annealing iyasiza futhi ukuthola izicubu ezifanayo kanye nezakhiwo kodwa azifanele izigaba ezinkulu.

4. I-Spheroidizing Annealing.

Inqubo yokwelapha ukushisa ye-spheroidizing carbide ukuze kutholwe i-pearlite eyimbudumbudu. Shisisa insimbi ku-Ac1 ngaphezu kuka-20- 30 ℃ futhi ugcine izinga lokushisa elingu-2- 4h ngemva kokupholisa. I-Spheroidization annealing isetshenziselwa kakhulu ukunciphisa ubulukhuni, ukwakheka okufanayo kanye nokwenza ngcono ukukwazi ukulungiselela ukucisha. Lena inqubo ye-carbon ephezulu ne-alloy steel ukuze kuthuthukiswe ukusebenza kwayo. Kunezindlela eziningi zokwenza inqubo ye-spheroidizing annealing, lokhu kungenziwa ngezindlela ezintathu:

- A) Uma i-spheroidizing annealing: shisisa insimbi ibe ngaphezu kwezinga lokushisa elibucayi ngaphezu kuka-120 ~ 30 ℃futhi uhlale isikhathi esithile, bese uyivumela ukuthi iphole kancane esithandweni sokupholisa. Ithishu yasekuqaleni ngaphambi kokufakwa kwe-anneal kufanele kube i-pearlite yeshidi elihle futhi akukho mesh ye-carburized evunyelwe.

- B) I-Isothermal spheroidizing annealing: shisisa insimbi ngemva kokugcina ukushisa, kanye nokupholisa kwesithando somlilo ngaphansi kwezinga lokushisa elibalulekile10 ~ 30 ℃. Ngemuva kwe-isothermal kanye nesithando somlilo kupholiswe cishe ku-500 ℃ noma ukupholisa komoya okuphuma kancane. Inezinzuzo eziningana ezifana nomjikelezo omfushane, i-uniform spheroidization kanye nokulawula ikhwalithi okulula.

- C) ukuphindaphinda kwe-spheroidizing annealing

5. I-Diffusion Annealing(I-Homogenizing annealing).

Inqubo yokwelapha ukushisa lapho ama-ingots, ama-castings, noma izikhala zishiselwa ezingeni lokushisa elingaphansi kancane kwezinga lokushisa elibalulekile isikhathi eside bese lipholiswa kancane ukuze kuqedwe ukungafani kwamakhemikhali. Ngakho-ke ukuqeda ukuhlukaniswa kwe-dendritic kanye nokuhlukaniswa kwesifunda ngesikhathi sokuqina kwe-ingot, kanye nokwenza i-homogenize ukubunjwa nesakhiwo. Izinga lokushisa le-diffusion annealing liphezulu kakhulu, ngokuvamile lingaphezu kwezinga lokushisa elibalulekile lika-100 ~ 200 ℃ amahora angu-10 ~ 15, okuncike ekuhlukaniseni kanye nebanga lensimbi. I-Diffusion annealing yekhwalithi ethile ephezulu steel alloy kanye ne-alloy castings kanye ne-ingot ngokuhlukaniswa okukhulu.

6. I-Stress Relief Annealing.

Ukuze kuqedwe ukucindezeleka okusele, insimbi ifudumala ekushiseni okungaphansi kwezinga lokushisa elibucayi (ngokuvamile i-500 ~ 650 ℃) ngemva kokugcinwa kokushisa, bese ipholiswa esithandweni. I-De-stressed annealing ayishintshi isakhiwo sensimbi.

7. Recrystallization annealing.

I-recrystallization annealing, eyaziwa nangokuthi i-intermediate annealing, iyinqubo yokwelapha ukushisa eshisa insimbi ekhubazekile ngaphezu kwezinga lokushisa le-recrystallization isikhathi esithile, ukuze okusanhlamvu okukhubazekile kuguqulwe kube okusanhlamvu okulinganayo okulinganayo ukuze kuqedwe ukuqina kokucubungula. kanye nokucindezeleka okusalayo. I-recrystallization kufanele yenzeke ekuqaleni ngenani elithile le-deformation yepulasitiki ebandayo bese kuba lokushisa elithile. Izinga lokushisa eliphansi kunawo wonke lapho ukuvuselelwa kabusha kwenzeka khona libizwa ngokuthi izinga lokushisa eliphansi kakhulu le-recrystallization. Ukushisisa kwezinga lokushisa le-recrystallization annealing kufanele libe ngaphezu kwezinga lokushisa eliphansi kakhulu lecrystallization engu-100 ~ 200 ℃ (izinga lokushisa elincane lokuhlanganisa kabusha insimbi elingaba ngu-450 ℃), ukupholisa kancane ngemva kokulondoloza ukushisa okufanele.

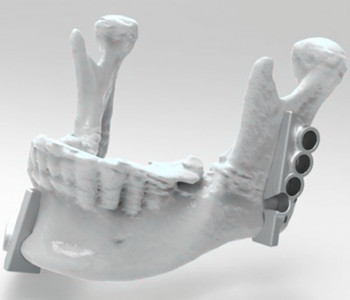

Ama-alloys e-Titanium asetshenziswe kabanzi ku-aerospace, imboni yamakhemikhali, imboni yenuzi, imishini yezemidlalo kanye nemishini yezokwelapha ngenxa yokumelana nokushisa okuphezulu, ukumelana nokugqwala okuphezulu, amandla aphezulu, ukuminyana okuphansi kanye nokuvumelana kwezinto eziphilayo. Izingxenye ze-Titanium alloy zisetshenziswe kabanzi emikhakheni yobuchwepheshe obuphezulu, njenge-F14, F15, F117, B2 kanye nezindiza zezempi ze-F22. Ingxenye ye-titanium esetshenziswe endizeni ye-Boeing 747 ngokulandelana ngokulandelana kwayo ingu-24%, 27%, 25%, 26% kanye no-42%. Kodwa-ke, izindlela zendabuko zokubumba nokuphonsa ukuze kukhiqizwe izingxenye ezinkulu ze-titanium alloy zinezinkinga eziningi, njengezindleko eziphezulu, inqubo eyinkimbinkimbi, izinga eliphansi lokusebenzisa impahla kanye nokucubungula okunzima kokulandelela, okuvimbela ukusetshenziswa kwayo okubanzi. Ubuchwepheshe bokuphrinta be-Metal 3D bungaxazulula lezi zinkinga ngokuyisisekelo, ngakho-ke sekuwubuchwepheshe obusha bokukhiqiza izingxenye ze-titanium alloy eminyakeni yamuva nje.

Ama-alloys e-Titanium asetshenziswe kabanzi ku-aerospace, imboni yamakhemikhali, imboni yenuzi, imishini yezemidlalo kanye nemishini yezokwelapha ngenxa yokumelana nokushisa okuphezulu, ukumelana nokugqwala okuphezulu, amandla aphezulu, ukuminyana okuphansi kanye nokuvumelana kwezinto eziphilayo. Izingxenye ze-Titanium alloy zisetshenziswe kabanzi emikhakheni yobuchwepheshe obuphezulu, njenge-F14, F15, F117, B2 kanye nezindiza zezempi ze-F22. Ingxenye ye-titanium esetshenziswe endizeni ye-Boeing 747 ngokulandelana ngokulandelana kwayo ingu-24%, 27%, 25%, 26% kanye no-42%. Kodwa-ke, izindlela zendabuko zokubumba nokuphonsa ukuze kukhiqizwe izingxenye ezinkulu ze-titanium alloy zinezinkinga eziningi, njengezindleko eziphezulu, inqubo eyinkimbinkimbi, izinga eliphansi lokusebenzisa impahla kanye nokucubungula okunzima kokulandelela, okuvimbela ukusetshenziswa kwayo okubanzi. Ubuchwepheshe bokuphrinta be-Metal 3D bungaxazulula lezi zinkinga ngokuyisisekelo, ngakho-ke sekuwubuchwepheshe obusha bokukhiqiza izingxenye ze-titanium alloy eminyakeni yamuva nje. Ingxubevange yokushisa ephezulu isho ingxubevange yensimbi eyi-super iron, nickel necobalt njengesisekelo futhi isengasebenza isikhathi eside ekushiseni okuphezulu okungu-600 ℃ noma ngaphezulu kanye nemvelo yokucindezeleka. Inamandla okushisa aphezulu, ukumelana okuhle nokumelana nokugqwala kanye nokumelana ne-oxidation kanye nepulasitiki enhle nokuqina. Njengamanje, ama-alloys angahlukaniswa cishe ngezigaba ezintathu: i-alloy esekelwe ku-Fe, i-nickel based alloy ne-cobalt alloy.

Ingxubevange yokushisa ephezulu isho ingxubevange yensimbi eyi-super iron, nickel necobalt njengesisekelo futhi isengasebenza isikhathi eside ekushiseni okuphezulu okungu-600 ℃ noma ngaphezulu kanye nemvelo yokucindezeleka. Inamandla okushisa aphezulu, ukumelana okuhle nokumelana nokugqwala kanye nokumelana ne-oxidation kanye nepulasitiki enhle nokuqina. Njengamanje, ama-alloys angahlukaniswa cishe ngezigaba ezintathu: i-alloy esekelwe ku-Fe, i-nickel based alloy ne-cobalt alloy.