Isingeniso esifushane sezinto ezisetshenziswa kabanzi zensimbi zokuphrinta kwe-3D

Ukuphrinta kwensimbi ye-3D, okubuye kwaziwe ngokuthi i-metal fusion, sekunqobe izimakethe ezintsha emkhakheni wezokundiza, wezokwelapha, wokwakha kanye newezimoto eminyakeni embalwa edlule ngezinzuzo zakho ezingenakuqhathaniswa kanye nokuba lula. Njengamanje, ubuchwepheshe bensimbi bokuphrinta be-3D bushesha futhi bungashibhile, bungasetshenziswa futhi ukwakha izakhiwo ezinkulu. Ubuchwepheshe bokuphrinta ikakhulukazi buhlanganisa i-selective laser sintering (SLS), i-electron beam fusion (EBM), i-selective laser fusion (SLM) kanye ne-laser engineered net shaping (LENS). I-SLM isebenzisa umthombo we-laser onamandla kakhulu ongancibilikisa impushana yensimbi ehlukahlukene, iyindlela esetshenziswa kakhulu. Impushana yensimbi esetshenziselwa amaphrinta e-3D asekhaya nakwamanye amazwe ngokuvamile yile: Insimbi yethuluzi, insimbi ye-Martensitic, insimbi engagqwali, i-titanium ehlanzekile ne-titanium alloy, i-Aluminium alloy, i-nickel base alloy, i-Copper base alloy, i-Cobalt-chromium alloy nokunye.

INSIMBI ENGAGQWALI

Insimbi engagqwali into yokuqala esetshenziswa ekunyatheliseni kwensimbi ye-3D ngenxa yokumelana kwayo okuhle namakhemikhali, ukumelana nezinga lokushisa eliphezulu kanye nezakhiwo ezinhle zemishini. Njengamanje, kunezinhlobo ezintathu zensimbi engagqwali ezisetshenziswa ekuphrinteni kwe-3D kwensimbi: i-Austenite insimbi engagqwali engu-316L, i-Martensite insimbi engagqwali engu-15-5PH kanye ne-Martensite insimbi engagqwali engu-17-4PH.

Insimbi engagqwali into yokuqala esetshenziswa ekunyatheliseni kwensimbi ye-3D ngenxa yokumelana kwayo okuhle namakhemikhali, ukumelana nezinga lokushisa eliphezulu kanye nezakhiwo ezinhle zemishini. Njengamanje, kunezinhlobo ezintathu zensimbi engagqwali ezisetshenziswa ekuphrinteni kwe-3D kwensimbi: i-Austenite insimbi engagqwali engu-316L, i-Martensite insimbi engagqwali engu-15-5PH kanye ne-Martensite insimbi engagqwali engu-17-4PH.

316L insimbi engagqwali ye-Austenitic, enamandla amakhulu nokumelana nokugqwala, ingancishiswa ibe izinga lokushisa eliphansi emazingeni okushisa ahlukahlukene. Isetshenziswa ezinhlelweni ezahlukahlukene zobunjiniyela njenge-aerospace kanye ne-petrochemical, kanye nokucubungula ukudla nokwelashwa.

15-5PH Insimbi engagqwali ye-Martensitic, eyaziwa nangokuthi i-Martensitic aging (i-precipitated hardening) insimbi engagqwali, inamandla aphezulu, ukuqina okuhle nokumelana nokugqwala, kuwukuqina okuqhubekayo kwensimbi engena-ferrite. Njengamanje, isetshenziswa kabanzi ku-aerospace, petrochemical, chemical, processing food, paper and metal processing industries.

17-4 PH Insimbi engagqwali ye-Martensitic, esenamandla aphezulu kanye nokuqina okuphezulu ngaphansi kuka-315 ℃, nokumelana okuqinile nokugqwala futhi ingaletha i-ductility enhle kakhulu njengesimo somshini we-laser.

I-TITANIUM ALLOY

Ama-alloys e-Titanium asetshenziswe kabanzi ku-aerospace, imboni yamakhemikhali, imboni yenuzi, imishini yezemidlalo kanye nemishini yezokwelapha ngenxa yokumelana nokushisa okuphezulu, ukumelana nokugqwala okuphezulu, amandla aphezulu, ukuminyana okuphansi kanye nokuvumelana kwezinto eziphilayo. Izingxenye ze-Titanium alloy zisetshenziswe kabanzi emikhakheni yobuchwepheshe obuphezulu, njenge-F14, F15, F117, B2 kanye nezindiza zezempi ze-F22. Ingxenye ye-titanium esetshenziswe endizeni ye-Boeing 747 ngokulandelana ngokulandelana kwayo ingu-24%, 27%, 25%, 26% kanye no-42%. Kodwa-ke, izindlela zendabuko zokubumba nokuphonsa ukuze kukhiqizwe izingxenye ezinkulu ze-titanium alloy zinezinkinga eziningi, njengezindleko eziphezulu, inqubo eyinkimbinkimbi, izinga eliphansi lokusebenzisa impahla kanye nokucubungula okunzima kokulandelela, okuvimbela ukusetshenziswa kwayo okubanzi. Ubuchwepheshe bokuphrinta be-Metal 3D bungaxazulula lezi zinkinga ngokuyisisekelo, ngakho-ke sekuwubuchwepheshe obusha bokukhiqiza izingxenye ze-titanium alloy eminyakeni yamuva nje.

Ama-alloys e-Titanium asetshenziswe kabanzi ku-aerospace, imboni yamakhemikhali, imboni yenuzi, imishini yezemidlalo kanye nemishini yezokwelapha ngenxa yokumelana nokushisa okuphezulu, ukumelana nokugqwala okuphezulu, amandla aphezulu, ukuminyana okuphansi kanye nokuvumelana kwezinto eziphilayo. Izingxenye ze-Titanium alloy zisetshenziswe kabanzi emikhakheni yobuchwepheshe obuphezulu, njenge-F14, F15, F117, B2 kanye nezindiza zezempi ze-F22. Ingxenye ye-titanium esetshenziswe endizeni ye-Boeing 747 ngokulandelana ngokulandelana kwayo ingu-24%, 27%, 25%, 26% kanye no-42%. Kodwa-ke, izindlela zendabuko zokubumba nokuphonsa ukuze kukhiqizwe izingxenye ezinkulu ze-titanium alloy zinezinkinga eziningi, njengezindleko eziphezulu, inqubo eyinkimbinkimbi, izinga eliphansi lokusebenzisa impahla kanye nokucubungula okunzima kokulandelela, okuvimbela ukusetshenziswa kwayo okubanzi. Ubuchwepheshe bokuphrinta be-Metal 3D bungaxazulula lezi zinkinga ngokuyisisekelo, ngakho-ke sekuwubuchwepheshe obusha bokukhiqiza izingxenye ze-titanium alloy eminyakeni yamuva nje.

I-TiAl6V4 (Gr5) ingxubevange yokuqala esetshenziswa ekukhiqizeni ukuphrinta kwe-SLM3D. Kodwa-ke, ukumelana ne-plastic shear deformation empofu kanye nokumelana nokugqoka kwe-titanium kunciphisa ukusetshenziswa kwayo ngaphansi kwezinga lokushisa eliphezulu, ukugqwala kanye nezimo zokumelana nokugqoka. Ngakho-ke, i-Re ne-Ni yethulwa ku-titanium alloys, futhi isifafaza se-3D esiphrintiwe se-Re-based Re-based sisetshenziswe ngempumelelo ekamelweni elivuthayo le-aero-injini, futhi izinga lokushisa lokusebenza lingafinyelela ku-2200%.

COBALT

H13 hot work tool steel ingenye yazo. Izinsimbi zamathuluzi zisetshenziswa kabanzi ezingxenyeni zezimboni ngenxa yokuqina kwazo okuhle kakhulu, ukumelana nokugqoka, ukumelana ne-deformation kanye nekhono lokugcina imiphetho yokusika emazingeni okushisa aphezulu. Izinsimbi ze-Martensitic, ezithatha i-Martensite 300 njengesibonelo, ezaziwa nangokuthi izinsimbi ze-maraging, ziphawuleka ngamandla azo aphezulu, ukuqina kanye nokuzinza kwe-dimensional ngesikhathi sokuguga. Ngenxa yokuqina kwayo okuphezulu nokumelana nokugqokwa, i-Martensite 300 ifaneleka ezinhlelweni eziningi zokufa njengesikhunta somjovo, ukukhishwa kwengxube yensimbi ekhanyayo, isitembu kanye ne-extrusion, futhi isetshenziswa kabanzi ku-aerospace, izingxenye ze-fuselage ezinamandla aphezulu kanye nezingxenye zemoto yomjaho.

I-ALUMINIUM ALLOY

Ama-alloys e-aluminium anezakhiwo ezinhle kakhulu zomzimba, zamakhemikhali nezomshini futhi asetshenziswe kabanzi emikhakheni eminingi. Kodwa-ke, izakhiwo ze-aluminium alloys ngokwazo (ezifana ne-oxidation elula, ukubonakaliswa okuphezulu kanye nokuhanjiswa kwe-thermal) kwandisa ubunzima bokukhiqiza okukhethiwe kwe-laser fusion. Kunezinkinga ezithile ezifana ne-oxidation, ingcindezi eyinsalela, amaphutha angenalutho kanye nokuminyana kwinqubo ye-SLM lapho kunyatheliswa ama-alloys e-aluminium. Lezi zinkinga zingathuthukiswa ngokuvikela ngokuqinile umkhathi, ukwandisa amandla e-laser nokunciphisa isivinini sokushanela. Njengamanje, i-SLM iphrinta i-aluminium alloy materials ikakhulukazi i-Al-Si-Mg series alloy efana ne-AlSi12 ne-AlSi10Mg. I-Aluminium-silicon 12 iyimpushana yensimbi enethayo engasindi esebenza kahle ngokushisa okushisayo. Ingasetshenziswa ezingxenyeni ezincanyana zodonga, njengezishintshisi zokushisa noma ezinye izingxenye zezimoto. Ingasetshenziswa futhi ku-prototype kanye nezingxenye zokukhiqiza ze-aerospace kanye nemboni yezindiza.Ukwengezwa kwe-silicon ne-magnesium kunikeza ingxubevange ye-aluminium amandla nokuqina okwengeziwe, okwenza ifanele udonga oluncane kanye nezingxenye zejometri eziyinkimbinkimbi, ikakhulukazi esimweni esihle sokushisa. ukusebenza kanye nesisindo esincane.

I-MAGNESIUM ALLOY

Njengengxube yesakhiwo esilula kunazo zonke, ingxubevange ye-magnesium inethuba lokushintsha insimbi ne-aluminium ingxubevange emikhakheni eminingi yohlelo lokusebenza ngenxa yamandla ayo akhethekile aphezulu kanye nezakhiwo zokudambisa. Isibonelo, ukusetshenziswa kwe-magnesium alloys engasindi ezingxenyeni zezimoto nezendiza kunganciphisa ukusetshenziswa kukaphethiloli kanye nokukhipha umoya. Ingxubevange ye-Mg inokuwohloka okuhle kakhulu kwe-in-situ kanye ne-biocompatibility, ne-modulus ephansi ye-Young futhi isondelene namandla amathambo omuntu. Inamathemba amaningi okusebenza ekufakweni kokuhlinzwa kune-alloy yendabuko.

I-ALLOY ESEMPERATURE ESIPHEZULU

Ingxubevange yokushisa ephezulu isho ingxubevange yensimbi eyi-super iron, nickel necobalt njengesisekelo futhi isengasebenza isikhathi eside ekushiseni okuphezulu okungu-600 ℃ noma ngaphezulu kanye nemvelo yokucindezeleka. Inamandla okushisa aphezulu, ukumelana okuhle nokumelana nokugqwala kanye nokumelana ne-oxidation kanye nepulasitiki enhle nokuqina. Njengamanje, ama-alloys angahlukaniswa cishe ngezigaba ezintathu: i-alloy esekelwe ku-Fe, i-nickel based alloy ne-cobalt alloy.

Ingxubevange yokushisa ephezulu isho ingxubevange yensimbi eyi-super iron, nickel necobalt njengesisekelo futhi isengasebenza isikhathi eside ekushiseni okuphezulu okungu-600 ℃ noma ngaphezulu kanye nemvelo yokucindezeleka. Inamandla okushisa aphezulu, ukumelana okuhle nokumelana nokugqwala kanye nokumelana ne-oxidation kanye nepulasitiki enhle nokuqina. Njengamanje, ama-alloys angahlukaniswa cishe ngezigaba ezintathu: i-alloy esekelwe ku-Fe, i-nickel based alloy ne-cobalt alloy.

I-Superalloy isetshenziswa kakhulu ezinjinini ezisebenza kahle kakhulu. Ezinjinini zesimanje ezithuthukile ze-aero, ukusetshenziswa kwezinto ezibonakalayo ze-superalloy kubala u-40% ~ 60% wengqikithi yesisindo senjini. Ukuthuthukiswa kwezinjini ze-aero zesimanje ezisebenza kahle kudinga izinga lokushisa eliphezulu kakhulu nokusebenza kwe-superalloy. Inqubo ye-metallurgical evamile yama-ingots ihamba kancane ekupholiseni, ezinye izakhi kanye nokuhlukaniswa kwesigaba sesibili kubucayi kuma-ingots. Ukuphrinta kwe-3D kuyindlela entsha yokuxazulula ibhodlela lobuchwepheshe ekwenzeni i-nickel alloy.

Ngenxa yalokho, I-Inconel 625 isetshenziswa kaningi ezingxenyeni zensimbi ezisetshenziswa olwandle nasekukhiqizeni uwoyela negesi. Isilinganiso 718 inguqulo eqinile yeminyaka engu-625. I-718 iyingxubevange esekwe nickel, enokumelana nokugqwala okuhle nokumelana nokushisa, ukwelula, ukukhathala kanye nezindawo ezinwabuzelayo, futhi ilungele izinhlelo zokusebenza ezisezingeni eliphakeme, njengezinjini eziphehla uphethiloli zezindiza nomhlaba. ama-turbines asekelwe. I-Inconel 718 alloy iyi-nickel base superalloy eyake yasetshenziswa futhi iyingxubevange esetshenziswa kakhulu injini ye-aero okwamanje.

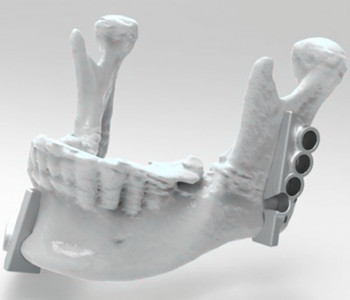

Ingxubevange ye-Cobalt-chromium inamandla amakhulu, ukumelana nokugqwala okuqinile, ukuhambisana okuhle kwe-biocompatibility kanye nezakhiwo ezingezona uzibuthe. Isetshenziswa kakhulu ekufakweni kokuhlinzwa, okuhlanganisa amalunga e-alloy artificial, amadolo ahlangene nama-hip joints, futhi ingasetshenziswa ezingxenyeni zenjini, izimboni zemfashini nezobucwebe.

Selokhu kwavela ubuchwepheshe bokuphrinta be-3D ngeminyaka yawo-1990, kusukela ezintweni zokuqala ze-polymer kuya kumpushana wensimbi, kuthuthukiswe futhi kwasetshenziswa ubuchwepheshe obusha obuningi, imishini emisha nezinto ezintsha. Kunezinhlobonhlobo zezinto zensimbi ezifanele ukuphrinta kwe-3D yezimboni, kodwa izinto ezimbalwa kuphela ezishiwo zempushana ezingahlangabezana nezidingo zokukhiqizwa kwezimboni. Nakuba ubuchwepheshe bokuphrinta be-3D be-metal powder buzuze ezinye izimpumelelo okwamanje, izinto ezisetshenziswayo kuseyisici esikhulu kunazo zonke futhi kunezidingo eziphakeme kakhulu ezintweni zokuphrinta ze-3D. Ngakho-ke, ukuthuthukiswa kobuchwepheshe bokuphrinta be-3D be-metal powder kusenendlela ende okufanele ihambe.