Insimbi engagqwali ye-Austenitic, njengoba negama layo lisho, inesakhiwo se-austenite. Ukwelashwa kokushisa kwensimbi engagqwali ye-austenitic kubaluleke kakhulu ngoba umsebenzi obalulekile we-austenitic insimbi engagqwali ukumelana nokugqwala. Uma ukwelashwa kokushisa kungalungile, ukumelana kwayo nokugqwala kuzoncishiswa kakhulu. Lesi sihloko sikutshela kakhulu ngakho. Ukwelashwa kokushisa kwezinsimbi ezingenasici ze-austenitic.

Insimbi engagqwali ye-Austenitic iyinsimbi evamile engagqwali (18-8 steel). Isibonelo, i-tableware eminingi ekhishini yenziwe nge-austenitic stainless steel. Insimbi engagqwali ye-Austenitic, njengoba negama layo lisho, inesakhiwo se-austenite. Ayinazibuthe futhi ayinakho ukuqina.

Insimbi engagqwali ye-Austenitic inokumelana nokugqwala okuqinile ezindaweni ezikhiqiza i-oxidizing. Indawo ebizwa ngokuthi i-oxidizing ingaqondwa kalula njengendawo equkethe umoya-mpilo owengeziwe. Insimbi engagqwali ye-Austenitic inokuqina okuhle futhi kulula ukuyicubungula futhi yakheke, ngakho inokusetshenziswa okubanzi.

Insimbi engagqwali ye-Austenitic isetshenziselwa ikakhulukazi izinhloso zokumelana nokugqwala, futhi ukwelashwa kokushisa kunomthelela omkhulu kuyo. Ukumelana nokugqwala nokumelana ne-asidi yensimbi engagqwali ye-austenitic ikakhulukazi kuncike ekudluleleni phezulu. Uma i-surface passivation ingakwazi ukugcinwa, izogqwala.

Ngakho-ke, insimbi engagqwali ye-austenitic ayiyona ibala eliphelele, ilungele kuphela izindawo ezine-oxidizing kanye nezindawo ezine-acidic. Ayinakho ukumelana okuqinile kuma-ion akhethekile. Ukwelashwa kokushisa kwensimbi engagqwali ye-austenitic ikakhulukazi kuthinta ikhono lokudlula lesendlalelo esingaphezulu, ngaleyo ndlela kuthinte ukusebenza kwayo kokugqwala.

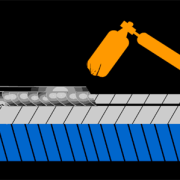

Ijika le-304 lensimbi engenasici, indawo ye-anode passivation ivela

Ukugqwala okufanayo kuyinto evamile kakhulu yokugqwala, futhi ukugqwala okufanayo kuncike ekusabalaliseni okufanayo kwama-elementi e-chromium. Ukwelashwa kokushisa kuthinta ukusatshalaliswa kwezinto ze-chromium, okuthinta ngokwemvelo ukumelana nokugqwala okufanayo kwensimbi engagqwali ye-austenitic.

Ukugqwala kwe-Intergranular nakho kungenye yezakhiwo ezibalulekile zokugqwala zokuhlola insimbi engagqwali ye-austenitic. Ngokuvamile, uma i-austenitic stainless steel izwela futhi inani elikhulu lama-carbides afana nobuhlalu likhuphuka emingceleni yokusanhlamvu, ukusebenza kwayo kwe-intergranular corrosion kuzoncipha kakhulu.

Uma insimbi engagqwali ye-austenitic izwela, ukugqwala okukhulu kwe-intergranular kuzokwenzeka ngisho nasendaweni ejwayelekile kakhulu ye-electrochemical.

Ukuqhekeka kwe-stress corrosion imodi yokwehluleka evame kakhulu ye-austenitic stainless steel. Wonke umuntu kufanele aqaphele ukuthi ukuqhekeka kwe-corrosion kuncike ezintweni ezimbili eziyinhloko:

Okokuqala, kufanele kube nokucindezeleka, okungase kusetshenziswe ukucindezeleka noma ukucindezeleka okusalayo;

Okwesibili, ama-ion azwela ukubola kwengcindezi, njengama-halogen ion, ikakhulukazi ama-chloride ion, yiwo avame kakhulu.

Lapho kusetshenziswa insimbi engagqwali ye-austenitic, ikhono layo lokumelana nokucindezeleka ngokuvamile alisetshenziswa, ngakho-ke ukunakwa okukhethekile kufanele kukhokhwe ekucindezelekeni okusalayo ngoba endaweni equkethe i-chloride ion, ukucindezeleka okusele kuzobangela ukuqhekeka kokugqwala kwengcindezi. Indlela yokususa ingcindezi eyinsalela ukuqeda ingcindezi.

I-pitting corrosion iyindlela esabekayo kakhulu yokugqwala. Kuthiwa iwukugqwala okwesabisa kakhulu, futhi kufaneleka kakhulu ukusebenzisa isisho sasendulo ukuze sichaze le nkinga: “Ichweba elingamakhilomitha ayinkulungwane liwela esidlekeni sentuthwane.”

Kunezizathu ezimbili eziyinhloko zokuthi kungani ukugqwala kwe-pitting kwenzeka:

Okokuqala, uma ukwakheka kwezinto kungalingani, njengokuzwela, insimbi engagqwali ye-austenitic ijwayele ukugqwala umgodi;

Okwesibili, ukugcwala kwemithombo yezindaba elimaza imvelo ayilingani, okuphinde kube yimbangela yokugqwala komgodi.

Uma ukugqwala kwe-pitting sekwenzekile, ungqimba lwefilimu yasendaweni luzobhujiswa, futhi kuzoba nokuncintisana phakathi kwezifunda ezisebenzayo kanye ne-passivation. Uma i-passivation ingenzeki, ukugqwala kwe-pitting kuzoqhubeka kuze kube yilapho ingxenye ibhobozwa.

Insimbi engagqwali ye-Austenitic ayinakho iphuzu lokuguqulwa kwesigaba esiqinile ekamelweni lokushisa kuya kuzinga lokushisa eliphezulu. Inhloso eyinhloko yokwelashwa kokushisa ukuncibilikisa ama-carbides akhiqizwa ngesikhathi sokucubungula ku-matrix, ngaleyo ndlela enze ukusatshalaliswa kwezakhi ze-alloy kufane kakhulu.

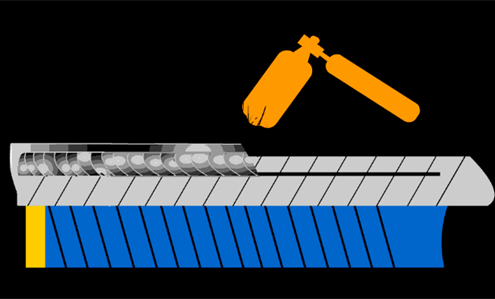

Ukushisisa insimbi engagqwali ye-austenitic ezingeni lokushisa eliphezulu ukuze kuncibilike ama-carbides ku-matrix, bese kupholiswa ngokushesha kuzinga lokushisa elilingana negumbi. Phakathi nale nqubo, i-austenitic insimbi engagqwali ngeke ibe lukhuni ngoba akukho ukuguqulwa kwesigaba futhi isimo se-austenitic sizohlala ekamelweni lokushisa. Le nqubo Ibizwa nge-solid solution treatment.

Ekwelashweni kwesixazululo esiqinile, inhloso yokupholisa ngokushesha iwukwenza kuphela ukusatshalaliswa kwama-athomu ekhabhoni kanye nezakhi ze-alloying kufane.

Ngesikhathi sokwelashwa kwesixazululo esiqinile sensimbi engagqwali ye-austenitic, uma izinga lokupholisa lihamba kancane kakhulu, njengoba izinga lokushisa lehla, ukuncibilika kwama-athomu ekhabhoni ku-matrix kuncipha, futhi ama-carbides azogaya. Ngaphezu kwalokho, ama-athomu e-carbon kulula kakhulu ukuhlanganisa ne-chromium ukuze akhe i-M23C6 carbides, esatshalaliswa emingceleni yokusanhlamvu. Ukuncipha kwe-Chromium kwenzeka emingceleni yokusanhlamvu futhi ukuzwela kwenzeka.

Ngemva kokuzwela kwenzeka ku insimbi engagqwali ye-austenitic, kufanele ishiselwe ngaphezu kuka-850ºC. Ama-carbides azoncibilika abe yisixazululo esiqinile, bese ukupholisa ngokushesha kungaxazulula inkinga yokuzwela.