Ososayensi baseMelika bathola ukuthi ingxubevange yokuqina okuphezulu kakhulu isenokusebenza okuphezulu kakhulu kubanda kakhulu

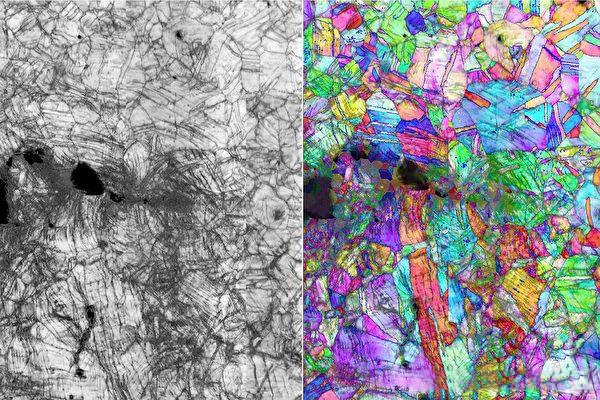

I-Berkeley National Laboratory e-United States ithole ukuthi ingxubevange eyakhiwe nge-chromium, i-cobalt, ne-nickel iyinto enzima kakhulu enezakhiwo ezimelana nokuphuka. Isithombe sibonisa indlela yokuphuka kwe-nanoscale kanye nokuguqulwa kwesakhiwo sekristalu esihambisana nayo Ingxubevange ye-CrCoNi ngesikhathi sokuhlolwa kokucindezeleka kuka-Kelvin okungu-20. Imifantu inweba ukusuka kwesokunxele kuye kwesokudla

Ngokukhula kwesidingo sokuhlola indawo yomuntu kanye nezifunda ezimbi kakhulu, abantu baqala ukufuna izinto zensimbi ezingasetshenziswa emazingeni okushisa aphansi. I-National Laboratory yase-United States ithole ingxubevange eyenziwe nge-chromium, i-cobalt, ne-nickel, engagcina ukuqina okuphezulu kakhulu emazingeni okushisa aphansi kakhulu futhi okwamanje iyingxubevange eqinile emhlabeni.

I-Lawrence Berkeley National Laboratory kanye ne-Oak Ridge National Laboratory e-United States ngokuhlanganyela babhala imiphumela yalokhu kuhlola ephepheni, elizoshicilelwa kumagazini i-Science ngo-December 2022. Lolu cwaningo lwasekelwa Ihhovisi Lesayensi Lomnyango Wezamandla WaseMelika.

Ososayensi bahlola izinsimbi eziyingxubevange ezenziwe “nge-chromium, i-cobalt, ne-nickel” kanye “ne-chromium, i-manganese, insimbi, i-cobalt, ne-nickel” ngezilinganiso ezilinganayo, futhi bahlola amanani azo okuqina kokuphuka. Kuyaphawulwa ukuthi "i-chromium manganese iron cobalt nickel" kanye "namanani wokuqina wokuphuka kwe-chromium we-"cobalt-nickel" alloy at minus 253.15°C angama-262 kanye nama-MPa-square amamitha angama-459, ngokulandelana.

Ngaphezu kwalokho, kutholwe ngokuhlolwa ukuthi “I-Chromium-Cobalt-Nickel” ingxubevange ibonise ukukhula kokuqina okudlula i-MPa-square root metres ngemva kokuqhekeka okuzinzile okungu-540 mm. Amanani angenhla amele ukuthi ingxubevange inokuqina okuphezulu kakhulu emhlabeni. Ososayensi baphinde bathola ukuthi ukuwohloka kwensimbi emazingeni okushisa aphansi kanye nesakhiwo sokuguquguquka emazingeni okushisa aphezulu kunemiphumela ehluke ngokuphelele.

Le ingxubevange akuyona nje i-ductile ngokwedlulele, kodwa futhi ithambile ngokwedlulele, futhi ngesikhathi esifanayo inamandla kakhulu (cishe imelana unomphela nokuguqulwa). Ngaphezu kwalokho, i-alloy inempahla ekhetheke kakhulu, amandla ayo kanye ne-ductility izokhula njengoba izinga lokushisa liyancipha, okuphambene nezakhiwo zezinto eziningi emhlabeni.

Ingxubevange eyenziwe chromium, cobalt, futhi nickel, okungokohlobo lwe-high-entropy alloy, ehlukile kwamanye ama-alloys ajwayelekile. Umehluko ukuthi amanye ama-alloy azoqukatha ingxenye ephezulu yensimbi eyodwa (isibonelo, insimbi, igolide, isiliva, noma ithusi, njll.) kanye nenani elincane lezinye izakhi noma izinsimbi (isibonelo, insimbi engagqwali, 18K igolide, njll.) ), kodwa ama-alloys ohlobo lwe-HEA, Yenziwa ngokuxuba isici ngasinye ngezilinganiso ezicishe zilingane.

Lawa ma-alloys, lapho amanani alinganayo e-elementi ngayinye exutshwe khona, abonakala enikeza into "amandla" aphezulu kakhulu kanye "ne-ductility" ehlanganiswe "ebulukhunini" bensimbi lapho kugcizelelwe.

Bathola ukuthi la ma-alloys ayengenayo i-microstructure eyinkimbinkimbi lapho ingcindezi isetshenziswa ekamelweni lokushisa, kodwa lapho ingcindezi isetshenziswa emazingeni okushisa aphansi kakhulu, i-microstructure yaqala ukuba yinkimbinkimbi. I-crystallization ku-alloy izoshintsha kusukela kuzinhlamvu eziyindilinga kuya emicucu, ngokuthambekela okunamandla kokuguqulwa kwendiza, futhi ekugcineni, yakha inqwaba yamabhendi e-criss-cross deformation. Ngakho-ke, kucatshangwa ukuthi lezi zinguquko zivumela insimbi ye-alloy ukuthi ithuthukise ukuqina kwayo.

“Ekuqaleni ama-athomu ensimbi akulengxubevange ayeyizinhlamvu ezibushelelezi futhi ezilula, kodwa ngomfutho wezinga lokushisa eliphansi, avela Lapho ikhubazeka, iqala ukuba nezithiyo eziningi ngaphakathi, okuyenza ibe namandla okuphuka okudlula kude lokho kwabaningi. izinto zokwakha.”

U-Andrew Jr., umqondisi we-Center for Electron Microscopy yalebhu, wanezela: “Lapho insimbi ikhubazekile, ukwakheka kwayo kuba yinkimbinkimbi kakhulu, futhi lolu shintsho lusiza ekuchazeni ukuthi kungani lubonisa lokhu kumelana nokuphuka.”

Ngaphezu kwalokho, uProfessor Rich uphinde wathi: "Le nto inenani lokuqina lokuphuka elifinyelela ku-500 MPa-square wamamitha wezimpande ezingeni lokushisa le-helium ewuketshezi (-253.15 ° C)."

USolwazi Rich wachaza: “Uma kuyunithi efanayo, inani lokuqina lokuphuka kwesiqephu se-silicon liyimitha yempande eyi-1 M MPa-square, inani lokuqina kokuphuka kwe-aluminium alloy fuselage elisetshenziswa ezindizeni zabagibeli yi-35 MPa-square metres, kanye nokuphuka kwensimbi okungcono kakhulu Ngenani lokuqina lamamitha angu-100 MPa-square wezimpande, inani elivezwe yile ngxubevange liyamangaza impela.”

Nokho, uSolwazi Ritchie uthe nakuba intuthuko yamanje ijabulisa, kusesekuseni kakhulu ukuthi ingasebenza. “Sidinga isikhathi esengeziwe sokuqonda kangcono izakhiwo zalolu hlelo ukuze silusebenzise ngokuzayo, sigweme izingozi abantu abangafuni ukuzibona uma abantu belusebenzisa.”

Igumbi lezindaba libike ukuthi uGeorge noRitchie, oprofesa bonjiniyela e-Oak Ridge National Laboratory, baqala ukucwaninga. ama-alloys e-chromium-cobalt-nickel eminyakeni eyishumi edlule, ukuhlanganisa insimbi ne-manganese kanye ne-iron-container chromium-manganese-iron-cobalt nickel alloy.

Lapho bebeka izinto ezingeni lokushisa le-nitrogen ewuketshezi (-196 °C) ukuze babone izinguquko ensimbi, bathola ukuthi ingxubevange inokuqina namandla okuhlaba umxhwele. Ukuze kuhlolwe amasampula ahlukahlukene kulokhu kushisa okubandayo, kwabathatha iminyaka eyi-10 ukuthola zonke izinhlobo zezisebenzi namathuluzi, futhi ekugcineni bafika emiphumeleni yokuhlola.