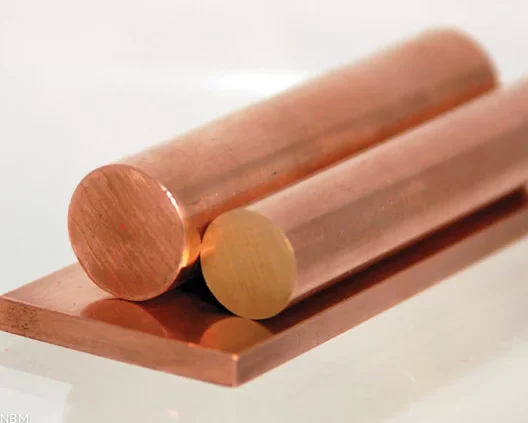

UNS C17500 Beryllium Copper Alloys

CuCo2Be—UNS C17500 (CW104C) Cobalt Beryllium Copper is good to excellent corrosion resistance and has Excellent cold workability and good hot formability.

CuCo2Be-C17500 (CDA 175) beryllium-cobalt copper is primarily used in industrial applications requiring the highest thermal or electrical conductivity with the addition of a cobalt alloy (2.40-2.70%).

C17500 also has good strength and hardness properties with electrical conductivity in the 45-60% range of copper and ultimate tensile and hardness properties close to 140 ksi and RB 100 respectively.

Chemical Composition:

| Element | ||||||

|---|---|---|---|---|---|---|

| Cu(1,2) | Fe | Al | Be | Co | Si | |

| (1) Cu value includes Ag.(2) Cu + Sum of Named Elements 99.5% min. | ||||||

| Min (%) | 0.4 | 2.4 | ||||

| Max (%) | Rem | 0.10 | 0.20 | 0.7 | 2.7 | 0.20 |

Mechanical Properties:

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| Density | 8.75 g/cc | 0.316 lb/in³ | |

| Mechanical Properties | Metric | English | Comments |

| Hardness, Rockwell B | 79 – 88 | 79 – 88 | |

| Tensile Strength, Ultimate | 515 – 585 MPa | 74700 – 84800 psi | |

| Tensile Strength, Yield | 345 – 515 MPa @Strain 0.200 % |

50000 – 74700 psi @Strain 0.200 % |

|

| Elongation at Break | 8.0 – 15 % | 8.0 – 15 % | In 50 mm |

| Modulus of Elasticity | 125 – 130 GPa | 18100 – 18900 ksi | |

| Fatigue Strength | 205 – 240 MPa | 29700 – 34800 psi | |

| Machinability | 40.0 % | 40.0 % | |

| Electrical Properties | Metric | English | Comments |

| Electrical Resistivity | <= 0.00000287 ohm-cm | <= 0.00000287 ohm-cm | |

| Thermal Properties | Metric | English | Comments |

| CTE, linear | 17.6 µm/m-°C @Temperature 20.0 – 200 °C |

9.78 µin/in-°F @Temperature 68.0 – 392 °F |

|

| Specific Heat Capacity | 0.420 J/g-°C | 0.100 BTU/lb-°F | |

| Thermal Conductivity | 17.3 W/m-K | 120 BTU-in/hr-ft²-°F | |

| Melting Point | 1030 – 1070 °C | 1890 – 1960 °F | |

| Solidus | 1030 °C | 1890 °F | |

| Liquidus | 1070 °C | 1960 °F | |

| Processing Properties | Metric | English | Comments |

| Processing Temperature | 980 °C | 1800 °F | Hot-Shortness Temperature |

| Solution Temperature | 900 – 925 °C | 1650 – 1700 °F | Large sections, 1 hour per inch or fraction of an inch |

| 900 – 955 °C | 1650 – 1750 °F | 10 minutes, water quench | |

| Ageing Temperature | 425 °C | 797 °F | 3-6 hours, for maximum strength |

| 470 – 495 °C | 878 – 923 °F | Commercial practice, 2-3 hours | |

| Hot-Working Temperature | 700 – 925 °C | 1290 – 1700 °F | |

| Precipitation Temperature | >= 482 °C @Time 7200 sec |

>= 900 °F @Time 2.00 hour |

Air |

Available Forms:

Bar, rod, round bar, solid bar, hollow bar, pipe, Flat bars, square bars, rectangular bars, hexagonal bars, and Customized shapes are available upon request.

Strip: ASTM B 534-07, MILITARY MIL-C-81021, B 888

Sheet: ASTM B 534-07, B 888

Rod: ASTM B 441-04, ASTM B 534, SAE J463, J461, BS 2872, BS 2874

Tube: ASTM B 937, SAE J463, J461

Profile: ASTM B 870-08, SAE J463, J461, BS 2874

Forgings: ASTM B 870-08, ASTM B 938, BS 2872

Applications:

Fuse clips, fasteners, switch and relay parts, electrical conductors, welding equipment, Corrosion-resistant components, Electrical connectors, Precision screw machined parts, Bearings, Plastic moulds, Current-carrying springs, and Welding electrodes.