American scientists discover the highest toughness alloy still has ultra-high performance in extreme cold

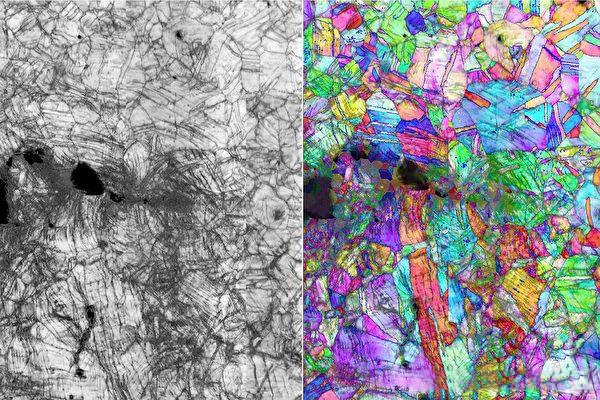

The Berkeley National Laboratory in the United States has discovered that an alloy composed of chromium, cobalt, and nickel is the hardest material with the most fracture-resistant properties. The picture shows the nanoscale fracture path and accompanying crystal structure deformation of CrCoNi alloy during the 20 Kelvin stress test. Cracks expand from left to right

With the increasing demand for human exploration of space and extreme regions, people began to look for metal materials that can be used at low temperatures. The National Laboratory of the United States discovered an alloy composed of chromium, cobalt, and nickel, which can maintain extremely high toughness at extremely low temperatures and is currently the toughest alloy in the world.

Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory in the United States jointly wrote the results of this experiment into a paper, which will be published in the journal Science in December 2022. This research was supported by the U.S. Department of Energy’s Office of Science.

Scientists study alloy metals made of “chromium, cobalt, and nickel” and “chromium, manganese, iron, cobalt, and nickel” in equal proportions, and test their fracture toughness values. It is observed that “chromium manganese iron cobalt nickel” and “chromium fracture toughness values of “cobalt-nickel” alloy at minus 253.15°C are 262 and 459 MPa-square root meters, respectively.

In addition, it was found through experiments that the “Chromium-Cobalt-Nickel” alloy exhibited a crack growth toughness exceeding 540 MPa-square root meters after a stable crack of 2.25 mm. The above values represent that the alloy has the highest toughness in the world. Scientists also found that the deformation of the metal at low temperatures and the deformation structure at high temperatures have completely different results.

This alloy is not only extremely ductile, but also extremely malleable, and at the same time very strong (almost permanently resistant to deformation). In addition, the alloy has a very special property, its strength and ductility will increase as the temperature decreases, which is the opposite of the properties of most materials in the world.

An alloy made of chromium, cobalt, and nickel, which belongs to the type of high-entropy alloy, which is different from other general alloys. The difference is that other alloys will consist of a high proportion of one metal (for example, iron, gold, silver, or copper, etc.) and small amounts of other elements or metals (for example, stainless steel, 18K gold, etc.), but HEA type alloys, It is made by mixing each element in almost equal proportions.

These alloys, in which equal amounts of each element are mixed, appear to endow the material with very high “strength” and “ductility” combined into the “toughness” of metal when stressed.

They found that these alloys did not have a complex microstructure when pressure was applied at room temperature, but when pressure was applied at extremely low temperatures, the microstructure began to become complex. The crystallization in the alloy will change from round grains to strips, with a strong tendency of plane deformation, and finally, form a bunch of criss-cross deformation bands. Therefore, it is speculated that these changes allow the alloy metal to enhance its toughness.

“Originally the metal atoms in this alloy were smooth and simple grains, but at low-temperature pressure, they appear When it deforms, it starts to have a lot of obstacles inside, which gives it a fracture toughness value that far exceeds that of most materials.”

Andrew Jr., director of the lab’s Center for Electron Microscopy, added: “When a metal deforms, its structure becomes very complex, and this transformation helps explain why it exhibits this resistance to fracture.”

In addition, Professor Rich also said: “This material has a fracture toughness value as high as 500 MPa-square root meters at the temperature of liquid helium (-253.15 ° C).”

Professor Rich explained: “If in the same unit, the fracture toughness value of a piece of silicon is 1 M MPa-square root meter, the fracture toughness value of the aluminum alloy fuselage used in passenger planes is 35 MPa-square root meters, and the best steel fractures With a toughness value of 100 MPa-square root meters, the value exhibited by this alloy is quite astonishing.”

However, Professor Ritchie said that while the current development is exciting, it is still too early to be practical. “We need more time to better understand the properties of this material so that we can put it into practical applications in the future, and avoid accidents that people don’t want to see when people use it.”

The newsroom reported that George and Ritchie, professors of engineering at Oak Ridge National Laboratory, began researching chromium-cobalt-nickel alloys a decade ago, combining the metal with manganese and iron-containing chromium-manganese-iron-cobalt nickel alloy.

When they put the material at the temperature of liquid nitrogen (-196 °C) to observe the changes in the metal, they found that the alloy had impressive toughness and strength. In order to test various samples at this cold temperature, it took them 10 years to find all kinds of personnel and tools, and finally came to the experimental results.