S7 High toughness shock-resisting tool steel

AISI S7 steel was originally derived from the United States commercial brand Finkl DRX, is a kind of medium carbon chromium molybdenum alloy shock resisting tool steel. It’s characterized by a good comprehensive property like hardenability, high strength, toughness, tempering stability and oxidation resistance of temperature, is suitable for load tools or dies working under high temperature and high impact and hammer forging die manufacturing. This steel has a high hardness after forging, so it needs softening and annealing to reduce the hardness and facilitate cutting. The available forms of S7 steel including round bar, drill rod, rectangular bar, ground flat bar, square bar and plate

Equivalent Material

| USA | GERMAN | CHINA |

| ASTM A681 T41907 | DIN 1.2357 | GB/T 1299 5Cr3MnSiMo1 |

S7 Chemical Composition

| C | Si | Mn | P | S | Cr | Mo | V |

| 0.45~0.55 | 0.20~1.00 | 0.20~0.90 | ≤0.030 | ≤0.030 | 3.00~3.50 | 1.30~1.80 | ≤0.35 |

S7 Mechanical Property

| Density | 0.283 lb/in3 (7833 kg/m3) |

| Modulus of Elasticity | 30 x 106 psi (207GPa) |

| Thermal Conductivity | 16.5 BTU/hr-ft-°F (28.5 W/m/°K) |

| Machinability | 70-75% of a 1% carbon steel |

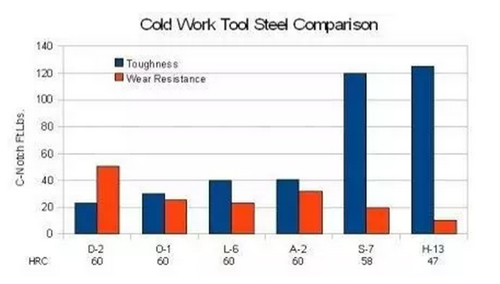

Comparison with A2 and H13

According to the analysis of hardness, wear-resistance and toughness (see the figure below), the performance of S7 is between A2 and H13, which can make up for the deficiency of both.

Hardness

The applied hardness of S7 is between 52~58HRC. Another 1~2HRC can be raised if proper heat treatment is applied.

Applications

S7 has high strength, toughness and wear resistance, making it a tool steel used for pneumatic tools and cutting tools such as punch, forging die, hammer, chisel, jig die, cutting tool and various cold and hot dies that require high hardness.

For more information about the S7 tool steel, contact us now!