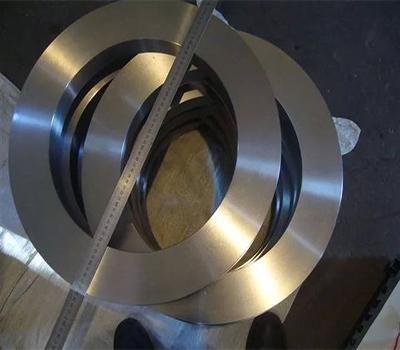

Precision machining of titanium alloy materials

As we all know, in the aerospace industry the precision machining for the material requirements is very high, of course, one side is in order to meet the special characteristics of aviation equipment, and more importantly, because of the aerospace environment impact. Because of the special environmental impact, the general materials on the market of course can not meet the needs of the environment, and are bound to need some special materials to replace them. Today to introduce you to a more commonly used material, that is, titanium alloy materials, especially in aerospace, which is more common, why is this material used more? Why is this material used more? It has something to do with its characteristics.

Titanium alloy, its specific gravity is small, determines the quality of small, high strength and thermal strength, determines the hardness and high-temperature resistance, and resistance to seawater and acid and alkali corrosion and a series of excellent physical and mechanical properties, determines that no matter what kind of environment can be used, there is also a point, the coefficient of deformation is very small, and therefore in the aerospace, aviation, shipbuilding, petroleum, chemical industry and other industries have been widely used.

Because titanium alloy materials have the above and ordinary materials are not the same place, but also decided that it is in precision machining is very difficult, many machining factories are not willing to process this material and do not know how to process this material. To this end, Xi’an Ruihua pump industry after a long period of understanding and communication with some titanium alloy processing customers, organized some small skills to share with you!

Due to the titanium alloy deformation coefficient being small, the cutting temperature is high, the tip of the tool stress is large, machining hardening is serious, resulting in cutting processing, the tool is easy to wear, chipping, cutting processing quality is difficult to ensure. How to do cutting processing then?

In titanium alloy cutting, cutting force is not big, work hardening is not serious, easy to get a better surface finish, but titanium alloy thermal conductivity is small, cutting temperature is high, tool wear is bigger, tool durability is low, the tool should be used with titanium chemical affinity role is small, high thermal conductivity, high strength, grain size of small tungsten and cobalt class carbide tools, such as YG8, YG3 and other tools. In titanium alloy in the turning process, chip breakage is a difficult problem in processing, especially the processing of pure titanium, In order to achieve the purpose of chip breakage, the cutting part can be sharpened into a full arc of the roll chip groove, shallow before and after the depth, before and after the narrow wide, so that the chips are easy to discharge outward, so as not to let the chips entangled in the surface of the workpiece, resulting in scratches on the surface of the workpiece.

The titanium alloy cutting deformation coefficient is small, the knife and chip contact area is small, cutting temperature is high, In order to reduce the generation of cutting heat, ① the front angle of the turning tool should not be too large, the front angle of the carbide turning tool is generally taken as 5-8 degrees, due to the high hardness of titanium alloy, in order to increase the impact strength of the turning tool, the back angle of the turning tool should not be too large, generally taken as 5 °, in order to strengthen the tip of the tip of the tool part of the strength of the tool, to improve the heat dissipation conditions, and to improve the tool’s In order to strengthen the strength of the tip part, improve the heat dissipation conditions, and improve the tool’s impact resistance, a larger absolute value of the negative edge inclination angle is used.

Control of reasonable cutting speed, should not be too fast, and the use of titanium alloy special cutting fluid cooling in the process, can effectively improve the tool durability, and choose reasonable feed.

Drilling is also more commonly used, titanium alloy drilling is more difficult, often in the process of burning and broken drill phenomenon. The main reasons are poor drill sharpening, untimely chip removal, poor cooling, and poor rigidity of the processing system. Depending on the diameter of the drill bit, grind a narrow horizontal edge with a width of 0.5㎜ in order to reduce the axial force and the vibration caused by resistance. At the same time, at a distance of 5-8㎜ from the tip of the drill bit, the edge band of the drill bit should be ground narrowly, leaving 0.5㎜ or so, which is favorable for the drill bit in chip removal. The geometry must be sharpened correctly, and the two cutting edges must be kept symmetrical, so as to prevent the drill bit from cutting on one side only, and the cutting force is all concentrated on one side, which will cause the drill bit to wear out prematurely, and even cause chipping phenomenon due to slipping. Always keep the cutting edge sharp. When the cutting edge becomes blunt, stop drilling immediately and resharpen the bit. If you continue to cut forcibly with a dull bit, the bit will soon burn and anneal due to high friction temperatures, resulting in the scrapping of the bit. At the same time, the hardened layer of the workpiece will be thickened, which will increase the difficulty of re-drilling in the future and the number of times to repair and sharpen the drill bit. According to the drilling depth requirements, should try to shorten the length of the drill bit, increase the thickness of the drill core to increase the rigidity, to prevent the drilling of holes due to jitter caused by the collapse of the edge. It has been proved by practice that the length of φ15 drill bit is 150 longer than that of 195. So the selection of length is also very important.

After the above two commonly used processing to see, titanium alloy processing is also relatively difficult, but after very good processing can still be processed out of good precision parts, titanium alloy parts for aerospace equipment.