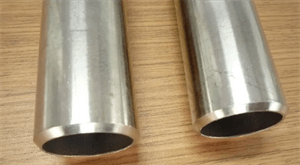

Tell the process and steps of making stainless steel seamless pipe

When I tell the production process and steps of making stainless steel seamless pipe, I inform in advance that the production process of stainless steel seamless pipe is different, and the corresponding production process is also different. For example, stainless steel seamless pipe has a division of cold-rolled pipe and hot-rolled pipe, for size requirements and high-quality requirements of stainless steel sanitary seamless pipe, one must use the production process of cold-rolled, cold-drawn, or a combination of both.

Stainless steel seamless tube production steps:

1, the choice of high-quality up to standard 304, 316L stainless steel raw material pipe billet by hollowing, head, annealing, and other operations.

2, after the completion of the above operations followed by multiple cold drawing (cold rolling) processes, the cold rolling of the pipe in the multi-roller mill, stainless steel pipe in the variable section of the circular hole groove, and immovable conical top head composed of ring-shaped hole type rolling.

3, after cold-rolled stainless steel tube will have a large yield strength coefficient, not suitable for flaring, bending, and other phenomena, in order to achieve stainless steel pipe sanitary standards, cold-rolled tubes also need to be bright annealing, demagnetization, pickling, straightening, and other steps.

5, stainless steel pipe pickling process, fittings in the pickling passivation at the same time can remove the surface of the workpiece oil, rust spots, weld spots, oxide layer, free iron, and other dirt, the surface becomes uniformly silvery white after treatment while preventing the metal from over corrosion and hydrogen embrittlement phenomenon, inhibit the generation of acid mist.

6, stainless steel pipe after the above process, the next is the polishing process, the inner wall of the pipe, the outer wall polishing mesh standard of 400 mesh, polishing treatment of the tube inside and outside the surface finish can reach the mirror standard (also known as sanitary standards).

7, polished stainless steel pipe needs to go through the metal flaw detection machine (or hydraulic test) for internal flaw detection and strict hand selection of steel pipe quality inspectors, qualified products can be packaged for delivery.

The production process of making stainless steel seamless pipe.

Production process: 1, steel making → 2, rolling round steel (skinning) → 3, perforation (annealing) → 4, cold drawing → 5, cold rolling (annealing, demagnetization, pickling, cleaning) → 6, inner wall polishing (400 mesh) → 7, outer wall polishing (400 mesh) → 8, air pressure testing → 9, surface testing → 10, paste trademark and certificate of conformity → 11, packaging → 12, factory