Application of titanium alloy in aviation industry

In the 1950s, the United States developed firstly the titanium alloy Ti-13V-11Cr-3Al in high-speed awacs, making this light-weight, high-strength, heat-treatable alloy was used for flight. In the 1960s, titanium alloy was widely used in non-military aviation engines and wide-body jets such as Boeing 747s. In the 1970s, the application of titanium alloy in aviation industry accounted for about 80% of the total titanium alloy market in the United States. In the other developed country such as Europe, Russia and Japan, titanium and titanium alloy applied on aircraft has increased significantly. Titanium is another new lightweight structural material applied in aerospace and aviation field after steel and aluminum alloy, and its application level has become an important mark to measure the advanced level of aircraft material selection.

Ti for aircraft body and frame

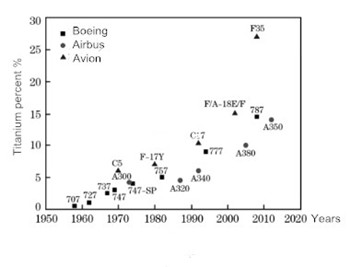

Titanium alloy is one of the important structural materials of aircraft body and frame. As a kind of weight reduction material, titanium alloy used in commercial and military aircraft has increased steadily in the past 50 years and the usage of titanium alloy on military aircraft has reached 30%~40%. The United States is the first country to successfully apply the design criteria of damaged safety and damage tolerance to advanced fighter aircraft. The F-22 fighter uses a large amount of damage tolerance titanium alloy and its large integral components to meet the design requirements of high weight loss and long life. The amount of titanium alloy in civil aircraft can also account for about 10%~15% of its total usage, among which the Boeing 787 airframe reaches 15%, which sets the highest record of titanium alloy used in the airframe. Modern aircraft fuselage, hydraulic pipes, landing gear, cockpit window frames, skin, fasteners, doors, wing structure, fan blades, compressor blades and other parts are mostly made of titanium alloy.

Ti for gas engine

titanium alloy is the main aviation material of Gas turbine engine, which accounts about 30% of the structure quality of modern turbine engine. Titanium alloy for engine design can further reduce the quality of the compressor blade and fan blade, prolong the life of the parts and repair cycle, so as to ensure the safety and stability of the aircraft. Compressor blades and the compressor set are the earliest engine parts made of titanium alloy, modern jet engines large front fan blades and spinning is also made of titanium alloy, these parts required materials under the working conditions of high temperature (300 ~ 600 ℃) has high specific strength, high temperature creep resistance, fatigue strength, rupture strength and stability.

With the improvement of thrust-weight ratio of aero engine, the high-pressure compressor outlet temperature increase leading to temperature of blade and disc rising, solid solution strengthening titanium alloy highest working temperature increased from 350 ℃ to 600 ℃. Alpha-Beta Titanium Alloys Ti-6AI – 4V is the main material under 400 ℃ for the fan blades and compressor 1, level 2 blades. At present, the fan blades and other parts of jet engines are mostly made of new titanium alloy alloy alloy alloy alloy sheaths. For example, The titanium alloy sheath used on the front and tip of the 747-8GENX engine fan blades has only been replaced three times in 10 years, proving that the titanium alloy fan blades withstood the rigorous test on the Boeing 777 aircraft.

The titanium and its alloy have found a large and diverse market in the aerospace industry such as commercial and military aircraft, space applications, missiles and various subsystems like engines and accessories. Lkalloy has a large stock range of materials ready for immediate supply to the aerospace industry. We even have built up a collection of other aerospace grades in stainless steel, nickel and copper-based alloys to meet the needs of more demanding safety critical components.