Do you know the importance of preheating before welding and post-weld heat treatment?

The importance of preheating before welding and post-weld heat treatment

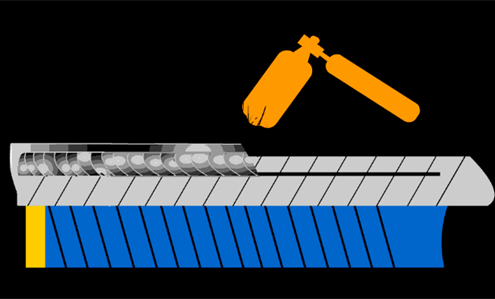

Preheat before welding

Preheating before welding and heat treatment after welding are very important to ensure welding quality. The welding of important components, the welding of alloy steel and the welding of thick parts all require preheating before welding. The main functions of preheating before welding are as follows:

(1) Preheating can slow down the cooling rate after welding, facilitate the escape of diffuse hydrogen in the weld metal, and avoid hydrogen-induced cracks. At the same time, it also reduces the hardening degree of the weld and heat-affected zone and improves the crack resistance of the welded joint.

(2) Preheating can reduce welding stress. Uniform local preheating or overall preheating can reduce the temperature difference (also called temperature gradient) between the workpieces to be welded in the welding area. In this way, on the one hand, the welding stress is reduced, and on the other hand, the welding strain rate is reduced, which is helpful to avoid welding cracks.

(3) Preheating can reduce the constraint of welded structures, especially in corner joints. As the preheating temperature increases, the crack incidence rate decreases.

The selection of preheating temperature and interlayer temperature is not only related to the chemical composition of the steel and welding rod, but also related to the rigidity of the welding structure, welding method, ambient temperature, etc., and should be determined after comprehensive consideration of these factors. In addition, the uniformity of the preheating temperature in the thickness direction of the steel plate and the uniformity in the weld area have an important impact on reducing welding stress. The width of local preheating should be determined according to the restraint condition of the workpiece to be welded. Generally, it should be three times the wall thickness around the weld area, and should not be less than 150-200 mm. If the preheating is uneven, instead of reducing the welding stress, it will increase the welding stress.

Post weld heat treatment

The purpose of post-weld heat treatment is threefold: eliminate hydrogen, eliminate welding stress, and improve the weld structure and overall performance.

Post-weld hydrogen elimination treatment refers to the low-temperature heat treatment performed after the welding is completed and the weld has not yet cooled to below 100°C. The general specification is to heat to 200~350℃ and keep warm for 2-6 hours. The main function of post-weld hydrogen elimination treatment is to accelerate the escape of hydrogen in the weld and heat-affected zone, and is extremely effective in preventing welding cracks during welding of low-alloy steel.

During the welding process, due to the uneven heating and cooling, as well as the constraints or external constraints of the component itself, welding stress will always be generated in the component after the welding work is completed. The existence of welding stress in components will reduce the actual load-bearing capacity of the welded joint area and cause plastic deformation. In severe cases, it will also cause damage to the component.

Stress relief heat treatment is to reduce the yield strength of the welded workpiece under high temperature to achieve the purpose of relaxing the welding stress. There are two commonly used methods: one is overall high-temperature tempering, that is, placing the entire weldment into a heating furnace, slowly heating it to a certain temperature, then keeping it warm for a period of time, and finally cooling it in the air or in the furnace. This method can eliminate 80%-90% of welding stress. Another method is local high-temperature tempering, that is, only heating the weld and its surrounding area, and then slowly cooling it to reduce the peak value of the welding stress and make the stress distribution gentler, thereby partially eliminating the welding stress.

After welding of some alloy steel materials, the welded joints will have hardened structures, which will deteriorate the mechanical properties of the materials. In addition, this hardened structure may cause joint damage under the action of welding stress and hydrogen. If after heat treatment, the metallographic structure of the joint is improved, the plasticity and toughness of the welded joint are improved, thereby improving the comprehensive mechanical properties of the welded joint.