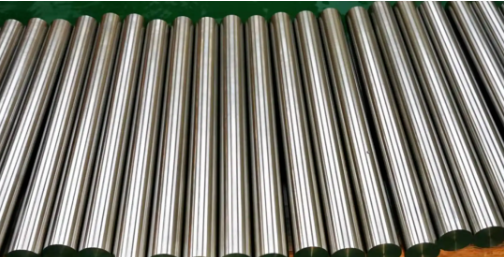

Titanium rod manufacturers introduce methods to identify fake and inferior products!

Many titanium rod manufacturers want to buy high-quality titanium rods when they buy titanium rods, but how to distinguish the quality of titanium rods? titanium rod manufacturers teach us how to make titanium rods good or bad from many aspects and angles.

1. The appearance of counterfeit and inferior titanium rods often has pockmarks.

The pockmarked surface is due to the serious wear and tear of the rolling groove, which leads to the irregular and uneven surface of the titanium material. Because manufacturers of counterfeit and inferior titanium rods seek to make profits, there are often overruns in grooving and rolling.

2. False and inferior titanium rods are easy to scratch. The reason is that the manufacturers of fake and inferior titanium rods have poor equipment, which is prone to burrs and scratches on the surface of titanium materials. Deep scratches reduce the strength of titanium.

3. The horizontal ribs of fake and inferior titanium rods are thin and low, and often appear to be full and dissatisfied. The reason is that in order to achieve a large negative tolerance, the reduction in the first few passes of the finished product is too large, the iron shape is too small, and the hole shape is not full.

4. False and inferior titanium rods are prone to folding.

Folding is a variety of fold lines formed on the surface of titanium rods, and this defect often runs through the longitudinal direction of the entire product. The reason for the folding is that the counterfeit and inferior manufacturers pursue high efficiency, and the reduction is too large, resulting in ears. Folding occurs during the next rolling process. The folded product will crack after bending, and the strength of the titanium material will be greatly reduced.

5. Fake and inferior titanium rods are prone to scarring on the surface.

There are two reasons: (1) The raw materials of fake and inferior titanium rods are uneven and have many impurities. (2) The guides and guards of fake and inferior material manufacturers are poorly equipped and easily stick to titanium. These impurities are prone to scarring after biting the roll.

6. Cracks are easy to occur on the surface of fake and inferior materials. The reason is that the billet is adobe, and the adobe has many pores. During the cooling process, the adobe suffers from thermal stress, cracks occur, and there are cracks after rolling.

7. False and inferior titanium rods have no metallic luster and are light red or similar in color to pig iron. There are two reasons for this. Two, its blank is adobe. The rolling temperature of fake and inferior materials is not standardized, and their titanium temperature is measured visually, so they cannot be rolled according to the regular austenite region, and the function of titanium materials is naturally unqualified.

8. The cross-section of fake and inferior titanium rods is elliptical. The reason is that in order to save materials, the reduction amount of the first two passes of the finished roll is too large. specification.

The above is all the content shared by the titanium rod manufacturer, I hope you can like it, welcome your consultation!