Corrosion resistance analysis of duplex stainless steel S32205 plate

Duplex stainless steel S32205 combines the advantages of Ferrite and Austenite steel. It characterized good corrosion performance excellent welding performance, is widely used in industry and components like chemical processing, paper manufacturing, desalination equipment, firewalls, bridges, pressure vessels, heat exchangers, turbine blades and transmission shafts of offshore systems.

The higher content of chromium, molybdenum and nitrogen alloying makes the duplex stainless steel S32205 have good corrosion resistance. If the duplex stainless steel contains at least 30% ferrite in the microstructure structure, its corrosion resistance is much better than that of the austenitic stainless steel 304 or 316. However, ferrite is sensitive to hydrogen embrittlement, so in environments or applications where hydrogen may enter the metal and lead to hydrogen embrittlement, duplex stainless steel 2205 does not have high corrosion resistance at this time. Corrosion of duplex stainless steel 2205 including: pitting corrosion (critical pitting corrosion temperature CPT, pitting corrosion weightlessness, pitting corrosion potential); Intergranular corrosion (critical crack corrosion temperature CCT, crack corrosion weightlessness); Stress corrosion test (boiling magnesium chloride, hydrogen sulfide stress corrosion). This article is to analyze the corrosion resistance of 2205 steel plate from the test results.

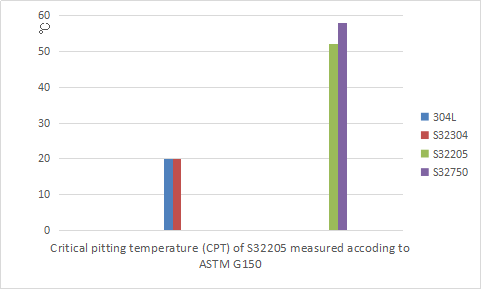

Pitting corrosion resistance

For a specific chloride environment, each grade of stainless steel can be described by the critical point corrosion temperature (CPT), above which the pitting corrosion begins to occur and can develop to the extent visible to the naked eye within 24 hours.No pitting occurs below this temperature. It is a representation of a particular stainless steel grade and environment. The table below showed pitting corrosion rate of S32205 according to ASTM A923 06C:

| Test | Testing temperature,℃ | Testing time, h | Corrosion rate,mg/d㎡.h |

| S32205 | 25±1 | 24 | 1.21 |

Intergranular corrosion resistance

Intergranular corrosion often appears at joint gaskets, sediment bottoms, and bolt joints. There is a similar critical temperature for intergranular corrosion, that is the critical crevice corrosion temperature (CCT), which depends on the stainless steel specimen, the chloride environment, and the characteristics of the crevice (compactness, length, etc.). Because of the geometry of the gap and the fact that it is difficult to present the same gap size in practice, the CCT measurement data are more dispersed than the critical point corrosion temperature (CPT). For the same grade of steel and the corrosion environment, CCTS tend to 15 ~ 20 ℃ lower than the CPT. The table below showed intergranular corrosion resistance of S32205 measured according to ASTM A923:

| S32205 | Time(hour) | Corrosion | ||

| Corrosion rate | 48h | 96h | 144h | No |

| 0.385 | 0.124 | 0.120 | ||

Stress corrosion resistance

Like many materials, duplex stainless steel is prone to stress corrosion fracture under certain conditions. This may occur at high temperatures, in environments containing chlorides or in media that are prone to hydrogen cracking. Environmental conditions in which stress corrosion cracking may occur in duplex stainless steel such as a 42% boiling magnesium chloride solution test, a droplet evaporation test in which the metal is exposed to a pressurized aqueous chloride system at a high temperature (the temperature in the system may be higher than that at normal pressure). Table 3 showed stress corrosion resistance of S32205 below:

| Testing standard | Stress | Time | Cracking or not | Evaluation |

| ASTM A923 | 0.8 Rp0.2 | 720hours | No | Qualified |

Tests have proved that compared with austenitic stainless steel and ferrite stainless steel, duplex stainless steel has better corrosion resistance. The 2205 stainless steel plate sample used in the test is according ASTM A240 and with a size of 1600*2500*10mm, We also supply a wide range of metals for a variety of applications. Our stock including stainless steel, tool steel, titanium, brass and copper. Any metal projects, call us now!