What’s the difference between brass and bronze?

In the last article, we discussed “what’s the admiralty brass”, today let us take the “brass” on the table. As the two of frequently used of copper alloy, they indeed have various of similarities more than the literalness, sometimes brass and bronze are a source of confusion and people often mix them up, Can you tell the difference between them? If you are facing the same confusion, this article will be a timely help.

Alloying difference

Both brass and bronze include a small range of other elements including arsenic, lead, phosphorus, aluminum, manganese, and silicon. Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties. In contrast, bronze is an alloy of copper and tin. There are many different bronze alloys, but typically modern bronze is 88% copper and 12% tin.

Surface difference

The most intuitive and visual difference is the color of the metal surface. Bronze is characterized by its reddish brown color (depending on the bronze alloys) while brass has a dull-gold surface. Brass can range in color from red to yellow depending on the amount of zinc added to the alloy. You can also tell the difference between brass and bronze from its surface.

Property difference

Brass has higher malleability than bronze. The relatively low melting point of brass various from 900 to 940℃, depending on composition. Its flow characteristics make it a relatively easy material to cast. By varying the proportions of copper and zinc, the properties of the brass can be changed, allowing hard and soft brasses.

Compared with brass, bronze is hard and brittle. It has a higher melting point and melts at 950℃, that also depends on the amount of tin percent. Bronze resists seawater corrosion and metal fatigue more than steel and is also a better conductor of heat and electricity than most steels.

Application difference

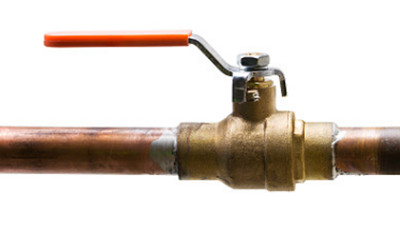

The different property leads to the difference of application. Brass is commonly used in the production of some complex shaped stamping products, such as condensing pipe, drainage pipe, shell and so on, or some small hardware, mechanical parts. Brass is also used for decoration for its bright gold-like appearance or where need low friction such as locks, gears, bearings, doorknobs, musical instruments and even zippers.

The different property leads to the difference of application. Brass is commonly used in the production of some complex shaped stamping products, such as condensing pipe, drainage pipe, shell and so on, or some small hardware, mechanical parts. Brass is also used for decoration for its bright gold-like appearance or where need low friction such as locks, gears, bearings, doorknobs, musical instruments and even zippers.

Because of its good performance of resistance to corrosion and hardness, Bronze is used in some elastic elements, cables or conductive materials even sculptures, musical instruments and medals, and in industrial and nautical applications such as bushings and bearings.

Price difference

The price varies depending on which grades you are comparing and alloying elements mixed in. There are over 40 standard grades of brass with a zinc content varying from around 36-42%, while bronze with about 6- 12% tin. The price of zinc is lower than copper while the tin is high than copper, sometimes due to the manufacturing processes, for casting or forging. In general, bronze is usually more expensive than brass.

While these two “red metals” may look similar, they are actually quite different. Visit our other copper metals, click here

References:

http://en.wikipedia.org/wiki/Brass