Heat treatment of Beryllium Copper C17200

The heat treatment of Cu-Be alloy is mainly solid solution annealing and aging hardening. Unlike other copper alloys whose strength is obtained only by cold machining, wrought copper beryllium is obtained by cold machining and hot aging hardening processes up to 1250-1500 Mpa. Aging hardening is often referred to as precipitation hardening or heat treatment. The ability of beryllium copper alloy to accept this heat treatment is superior to other alloys in terms of forming and mechanical properties. For example, complex shapes can be achieved at the highest strength and hardness levels of any other copper-base alloy, that is, in the rolling and subsequent aging state of the material. The following text describes in detail the aging hardening process of high strength Cu-Be alloy C17200, as well as the specific heat treatment of forging and casting alloys, recommended heat treatment equipment, surface oxidation and general solution annealing methods.

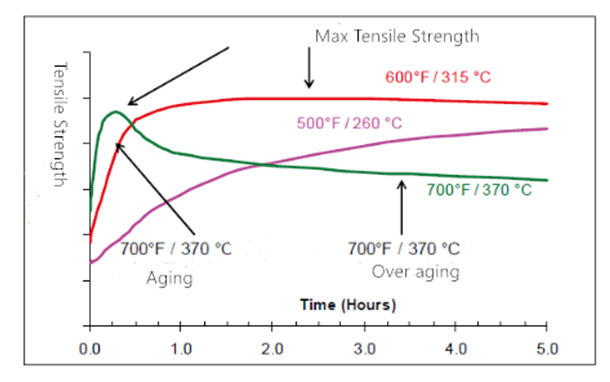

During aging hardening, microscopic beryllium-rich particles are formed in the metal matrix, a diffusion-controlled reaction whose strength varies with aging time and temperature. The recommended standard time and temperature allow the parts to reach their peak strength within two to three hours without compromising strength due to prolonged exposure to temperature. For example, the C17200 alloy response curve in the figure shows how low temperature, standard temperature, and high aging temperature affect the peak performance of the alloy and the time required to reach peak strength.

As can be seen from the figure, at low temperatures of 550°F(290°C), the strength of C17200 increases slowly and does not peak until about 30 hours later. At a standard temperature of 600°F(315°C) for 3 hours, the strength of C17200 changed little. At 700°F(370°C), the intensity peaks within 30 minutes and drops almost immediately. In short, as the aging temperature increases, both the time required to reach the peak intensity and the maximum intensity available decrease.

C17200 Copper Beryllium can be aged at different strengths. Aging peak refers to aging to the maximum intensity. The alloys that have not aged to their maximum strength are unaged, and alloys that have exceeded their maximum strength are over-aged. Under-aging Cu-Beryllium increases toughness, uniform elongation and fatigue strength, while over-aging increases conductivity, thermal conductivity and dimensional stability. Copper beryllium doesn’t age at room temperature even if it’s stored for a long time.

The allowable deviation of aging hardening time depends on furnace temperature and final performance requirements. In order to reach the optimum age at standard temperature, the furnace time is generally controlled within ±30 minutes. For high-temperature aging, however, more precise timing is needed to avoid averaging. For example, the aging time of C17200 at 700°F(370°C) must be controlled within ±3 minutes to maintain peak performance. Similarly, due to the sharp increase of aging response curve at the initial stage, insufficient aging also requires strict control of process variables. In a standard aging hardening cycle, heating and cooling rates are not important. However, to ensure that parts do not start to age before they reach temperature, thermocouples can be placed to determine when the desired temperature has been reached.

Aging Hardening Equipment

Recirculating air furnace. The temperature of the recirculated air furnace is controlled at ±15°F(±10°C). It is recommended for the standard aging hardening of copper-beryllium parts. These furnaces are designed to accommodate large and small volumes of parts and are ideal for drum stamping parts on the carrier of aging. However, due to its pure thermal quality, it is necessary to avoid insufficient aging or too short the aging cycle of mass parts.

Chain Aging Furnace. Steel strand aging furnace with a protective atmosphere as a heating medium is suitable for processing large quantities of beryllium copper coil, usually in a long furnace, so that the material can be expanded or curled. This allows for better control of time and temperature, avoiding partial uniformity and the ability to control special periods of insufficient or high temperature/short time aging and selective hardening.

Salt Bath. We also recommend the use of salt baths to age harden beryllium copper alloys. Salt baths provide quick and even heating and are recommended in any temperature hardening range, especially for short periods of high-temperature aging.

Vacuum Furnace. Vacuum aging of copper-beryllium parts can be accomplished successfully but care must be taken. Because vacuum furnace heating only relies on radiation, it is difficult to heat parts with large loads uniformly. The parts outside the load are exposed to more direct radiation than the parts inside, so the temperature gradient after heat treatment will change the performance. To ensure uniform heating, the load should be limited and the parts must be isolated from the heating coil. Vacuum furnaces can also be used to backfill inert gases such as argon or nitrogen. Similarly, unless the furnace is equipped with a recirculating fan, the parts must be protected.