What’s beryllium copper used for?

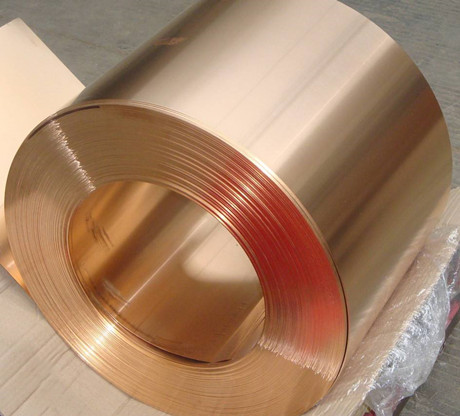

In last article, we discussed the question”What’s Beryllium Copper”, as well as we know, Beryllium Copper is also known as beryllium bronze, is a type of precipitated hardened copper alloy with beryllium as the main alloying element. Its density is 8.3g/cm³, 0.2~2.75% beryllium making its strength is twice that of other copper alloys. Beryllium copper alloy is a nearly perfect alloy with similar strength limit, elastic limit, yield limit and fatigue limit as special steel in mechanical, physical, chemical and mechanical properties and corrosion resistance. At the same time, it has high thermal conductivity, electric conductivity, hardness, abrasion resistance, temperature stability and creeps resistance. It also has the advantages of good casting performance, non – magnetic and no spark during impact.

There are different forms of classification for Beryllium copper alloy. It can be divided into deformable beryllium copper alloy and cast beryllium copper alloy according to the processing form of the final shape. It also can be divided into high strength and high elasticity beryllium copper alloy (C17000, C17200, C17300) and high conductivity copper-beryllium alloy (C17500, C17510) according to beryllium content and its characteristics. Beryllium copper provides a good processing performance, hardness after solid solution aging treatment can reach HRC38 ~ 43, a wide range of uses and more than 70% consumption of beryllium in the world is used for the production of beryllium copper. It is mainly used in mold industry, automobile industry, nuclear power industry, computer industry, electronic industry, temperature controller, cell phone battery, computer, automobile parts, micromotor, brush needle, advanced bearing, contact parts, gear, punch, all kinds of a non-spark switch, all kinds of welding electrodes and precision casting mold:

| Alloy | Parts | Applications |

| High strength beryllium copper | Reliable connector | Telecommunication, medical, computer, military, aviation, computer, connector |

| Durable switch | Automobiles, household appliances, telecommunications | |

| High sensitivity sensor | Bellows, reeds | |

| Highly elastic node | Battery contacts, wireless appliances, electromagnetic shielding | |

| High strength spring | Fixing clip, pressing ring, gasket | |

| High conductivity beryllium copper | High-temperature connectors | automotive, electrical, power distribution, fuse ends |

| High current relay | Automobile, electric appliance, electric motor | |

| Casting Beryllium copper | Tools | Safety and explosion-proof tools |

| Moulds | Children’s toys, plastic moulds, casting moulds, die casting moulds | |

| Devices | Submarine cable repeater, oil and gas | |

| High-temperature components | Welding electrode, rolling welding, generator shaft, steelmaking crystallizer |

Appendix table: 1. The common standards for Beryllium Copper

| ASTM B194 | Copper beryllium plate, sheet, strip and rolled bar |

| ASTM B196 | Copper beryllium bars and rods |

| ASTM B197 | Copper beryllium wire |

| ASTM B643 | Copper beryllium seamless tube |

| ASTM B441 | Copper – cobalt – beryllium and copper-nickel – beryllium bar/rod |

| ASTM B534 | Copper-cobalt-beryllium and copper-nickel-beryllium plates, sheets, strips and rolled bars |

2. The common material for Beryllium Copper

| Grades | Be | Ni+Co | Co+Ni+Fe | Pb | Cu |

| C17000 | 1.60~1.79 | ≥0.2 | ≤0.6 | — | Bal |

| C17200 | 1.80~2.00 | ≥0.2 | ≤0.6 | — | Bal |

| C17300 | 1.80~2.00 | ≥0.2 | ≤0.6 | 0.2~0.6 | Bal |