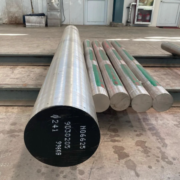

Welding of 625 nickel-based alloys

Nickel-based alloys have excellent corrosion resistance, good plastic toughness, and high strength, but 625 nickel-based alloys also have excellent overall performance, hot and cold deformation, smelting, casting, and welding, etc., widely used in aerospace, nuclear power, offshore oil recovery, oil and gas, and other industrial fields.

I. The properties of 625 alloy

Inconel 625 (UNS N06625), a widely used nickel-based alloy with Ni-Cr-Mo-Nb as the main additive element, has excellent all-round properties, with the following characteristics:

● High-temperature resistance

High Cr and Mo content, resulting in good resistance to high-temperature peeling and oxidation;

● Low-temperature resistance

good low-temperature toughness at -196°C due to the very high Ni content;

● High strength

High strength due to the high alloy type and content added and the multi-element compound reinforcement, which gives it a high strength, with a tensile strength of 760 MPa or more;

● Corrosion resistance

Alloy 625 exhibits excellent corrosion resistance in many media;

(1) Excellent resistance to pitting, crevice corrosion, intergranular corrosion, and erosion in chloride media;

(2) Excellent resistance to corrosion by inorganic acids such as nitric, phosphoric, sulphuric, and hydrochloric acids, as well as resistance to corrosion by alkalis and organic acids in oxidizing and reducing environments;

(3) Resistance to chloride ion corrosion and stress corrosion cracking;

(4) High Mo content, virtually corrosion free in seawater and industrial gas environments;

(5) Nb as a stabilizing alloy to reduce intergranular corrosion susceptibility;

II. Typical applications of 625 nickel-based alloys

● Pressure-bearing equipment

Nuclear power equipment, nuclear reactor components, boiler piping systems, heat exchangers, heat shields, valves, etc;

● Flue gas desulphurization systems

● Desulphurization towers, absorption towers, reheaters, flue gas inlet baffles, fans (wet) and flue pipes, etc;

● Chemical Equipment

Manufacture of equipment and components for use in acidic gas environments, e.g. sulphuric acid condensers, acetic acid reaction generators, etc;

● Aerospace

aerospace engine components, aircraft engines, structural components for astronautics, etc;

● Paper industry

Manufacturing of boilers, bleaching tanks, etc. for the pulp and paper industry;

● Seawater applications

For use in contact with seawater and subject to high mechanical stress, marine structures, and saltwater environments, especially where acidic chloride catalysts are used.

III. Welding precautions of 625 nickel-based alloys

(1) Clean weld seam is the key

The nickel content of the weld is high, and Ni can easily form low melting point eutectic with P, S, Si, Pb, etc., which can easily produce thermal cracks under the action of welding stress. Therefore, before welding, the workpiece and the surface of the wire should be thoroughly cleared of dirt, if necessary, with anhydrous alcohol or acetone wipe clean; the bevel should be used for the mechanical planing edge, clear root available sand grinding.

(2) The use of small specifications welding, to avoid coarse grain

Control welding heat input is less than 1.5 kJ/mm, the interpass temperature should be less than 100 ℃ (recommended ≤ 80 ℃), try to use small specifications, small specifications, fast welding, to prevent the weld and heat-affected zone grain growth, resulting in a decline in the toughness of welded joints.

(3) It is advisable to use low C content, low P, S and other impurities, containing Fe is not high welding consumables to avoid thermal cracking and corrosion resistance decline.

The above is all about 625 nickel-based alloys, welcome to Email: [email protected]