The difference between stainless steel seamless pipe and welded pipe

Stainless steel has good overall performance and good surface characteristics and has a wide range of applications in all walks of life. Similarly, stainless steel pipe is no exception. Stainless steel pipe is a kind of steel with a hollow section, generally divided into stainless steel seamless pipe and welded pipe. They also have certain differences in processing methods and performance, the differences are as follows:

First, the difference in the production process

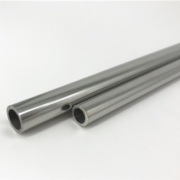

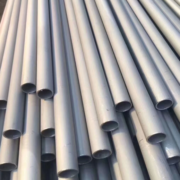

Stainless steel welded pipe is made of steel plate or strip after the unit and mold curling and forming welded, the tube wall generally has a weld; and a seamless tube is used as a round billet for perforation of raw materials, through the production process of cold rolling, cold drawing or hot extrusion made, there is no welding point on the tube.

Second, the difference in the appearance of steel pipe

Stainless steel welded pipe, the tolerance of its wall thickness is very small, and the wall thickness of the entire circumference is very uniform; the high precision of steel pipe, and high brightness of the inner and outer surface of the tube, can be arbitrarily sized; can do thin-walled tube. In contrast, the steel tube of seamless pipe has low accuracy, uneven wall thickness, low brightness of the inner and outer surface of the tube, high cost of sizing, and the inner and outer surfaces of the pockmark and black spot are not easy to remove. Therefore, the production of seamless pipe walls is usually thicker.

Third, the difference in performance and price

Seamless pipes are much higher than welded pipes in terms of corrosion resistance and pressure and high-temperature resistance. With the improvement of the production process of welded pipes, mechanical properties, and mechanical properties are slowly approaching seamless pipes. Seamless pipe is more complicated in the production process, and it is more expensive than welded pipe. Based on the characteristics and differences between seamless and welded stainless steel pipe, the application should be reasonably selected to achieve economical, beautiful, and reliable results: 1, used as a decorative tube, product tube, or prop tube, generally requires a good surface effect, usually choose stainless steel welded pipe; 2, for general lower pressure fluid transfer, such as the transfer of water, oil, gas, air and heating hot water or steam and other low-pressure systems, usually Choose stainless steel welded pipe; 3, for the pipeline used in industrial engineering and large equipment to transport fluids, as well as power stations, nuclear power plant boilers, require high-temperature and high-pressure, high-strength transport fluid pipeline, should be selected seamless stainless steel pipeline; 4, stainless steel welded pipe is generally used for liquid transport below 0.8MPa, a seamless pipe can be used to withstand the liquid transport above 0.8MPa. If the pressure requirements are not high, the use of welded pipe will be more economical.

Four, stainless steel seamless pipe advantages and disadvantages

Advantages: forming speed, high yield, can be made into a variety of cross-sectional forms to adapt to the needs of the conditions of use; cold rolling can make a large plastic deformation of steel, thereby increasing the yield point of steel. Hot rolling can destroy the casting organization of the ingot, refine the grain of the steel, and eliminate microstructural defects so that the steel organization is dense and the mechanical properties are improved. Disadvantages: 1, metal delamination – steel after cold rolling, the steel internal non-metallic inclusions (mainly sulfides and oxides, and silicates) are pressed into thin sheets, the phenomenon of delamination (sandwich). Delamination makes the steel along the thickness of the direction of the force performance greatly deteriorate, and there is a possibility of interlayer tearing when the weld expands. 2, uneven wall thickness – we are familiar with the metal has thermal expansion and contraction, due to rolling to the end of the cold-rolled steel pipe even if the length, and thickness are up to standard, the final cooling will still appear a certain negative difference, this The larger the negative difference, the worse the uniformity of the wall thickness. Therefore, the wall thickness, length, straightness, and ellipticity of cold-rolled seamless steel tubes can not be required to correct. 3, residual stress – due to uneven cooling, a variety of cross-sectional steel tubes have residual stress, the larger the cross-sectional size of the steel, the greater the residual stress, under the action of external forces has a certain impact on performance. Such as deformation, stability, fatigue resistance, etc. may have a detrimental effect. 4, poor surface finish – the inner surface of the steel pipe tensile marks are longitudinally distributed, showing a symmetrical or single linear fold, some through-length presence, and there is also a local presence.

Conclusion

Seamless pipe due to the complexity of the production process, the wall thickness uniformity is poor, the inner and outer wall surface roughness is poor, the actual operation is easy to make the chloride ion (or sulfur ion) substances (such as organic matter) bonded in the stainless steel pipe wall, the formation of a local anoxic acidic environment, so that the inner wall passivation film dissolved lose the protective effect on the metal, the metal directly in contact with the medium in the acidic environment, as the anode lost electrons and formed with water Hydroxide, hydroxide in the hydroxide is replaced by chlorine and dissolved in water, reducing the anodic passivation effect. Bond as a cathode to capture the hydrogen ions generated by the inner wall to form hydrogen gas, and with the inner wall of the metal reaction products together with the outward discharge, with the depth of the reaction, the wall of the metal is constantly corroded to form hole corrosion, the hole will gradually deepen and increase. When the temperature rises to 50 degrees above the pitting corrosion accelerates, the higher the temperature pitting corrosion faster. In large stress, conditions will also occur under the stress corrosion and stress corrosion expansion characteristics. In addition, the seamless tube in the welding process will produce a variety of instability, not easy to weld, and weld impermeable.

Five, stainless steel welded steel pipe advantages

Stainless steel welded steel pipe – uniform wall thickness of stainless steel strip in the gas protection without the addition of solder fusion welding once rolled into shape.

Advantages: 1. uniform wall thickness – the parent material for the forming strip, wall thickness consistency, high surface finish, to achieve industrial clean surface level 2B. 2. low residual stress – forming the steel tube using a high temperature higher than 1040 degrees for bright annealing stainless steel tube stress relief. 3. High weld strength – welding using melt welding, the material composition remains unchanged after high-temperature heat treatment of the weld and the parent material has the same intergranular structure, the weld is flattened, reverse bending, flaring and other damage experiments, the weld will not crack or cracks, burrs, and other problems. In addition to this, eddy current testing and water pressure or gas test should be done to ensure the quality of the tube. 4. Good consistency – good consistency of the outer diameter, wall thickness, length, and straightness of the tube, and high processing accuracy.