Seamless steel pipe hardness testing method

What are the seamless steel pipe hardness testing methods?

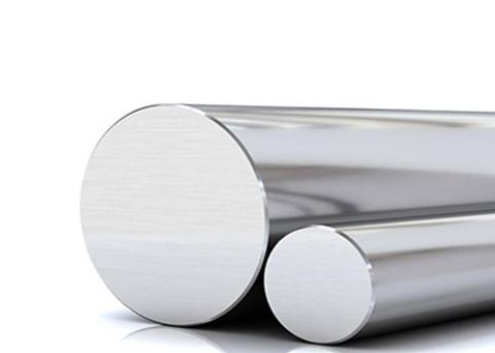

The hardness test of stainless steel should take into account its mechanical properties, which are related to the performance and quality of deformation, stamping, cutting, and other processing carried out with stainless steel as raw material. Therefore, all seamless steel pipes should be tested for mechanical properties. Mechanical properties test methods are mainly divided into two categories, one is the tensile test, and the other is the hardness test.

The tensile test is a seamless steel pipe made of specimens, in the tensile testing machine will be pulled to break the specimen, and then determine one or several mechanical properties, usually only determining the tensile strength, yield strength, elongation, and section shrinkage. The tensile test is the most basic mechanical properties of the metal materials test method, almost all metal materials, as long as the mechanical properties of the requirements, are specified tensile test. Especially for those materials whose shapes are not convenient for hardness tests, the tensile test becomes the only means of mechanical property inspection.

A hardness test is a rigid indenter according to the specified conditions slowly pressed into the surface of the specimen, and then testing the depth or size of the indentation, in order to determine the size of the material hardness. The hardness test is the simplest, quickest, and easiest to implement method in the mechanical property test of materials. The hardness test is non-destructive, with material hardness value and tensile strength value between the approximate conversion relationship. The fact that the hardness value of a material can be converted to a tensile strength value is of great practical significance.

Since the tensile test is not easy to test and it is convenient to convert from hardness to strength, people are increasingly testing only the hardness of the material and less often its strength. Especially due to the continuous progress and innovation of hardness tester manufacturing technology, some of the original can not directly test the hardness of the material, such as seamless steel tubes, stainless steel plates, and stainless steel strips, etc., are now possible to directly test the hardness. Therefore, there is a hardness test that gradually replaces the trend of the tensile test.

Most of the national standards in stainless steel materials are simultaneously specified in the tensile test and hardness test. For those materials that do not facilitate the hardness test, such as seamless steel pipe only provide for the tensile test. The stainless steel standard generally provides for cloth, Luo, dimensional three hardness test methods, determination of HB, HRB (or HRC), and HV hardness value, the provisions of the three hardness values can be measured only one of them.

Seamless steel pipe inside diameter of 6.0mm or more, a wall thickness of 13mm below the annealed seamless steel pipe, you can use a W-B75 type Wechsler hardness tester, which test is very fast, easy, and suitable for seamless steel pipe to do a quick and non-destructive qualification test. Seamless steel pipe inner diameter greater than 30mm, wall thickness greater than 1.2mm seamless steel pipe, using Rockwell hardness tester, test HRB, HRC hardness. Seamless steel pipe with an internal diameter greater than 30mm, wall thickness less than 1.2mm seamless steel pipe, using surface Rockwell hardness tester, test HRT or HRN hardness. Seamless steel pipe with inner diameter less than 0mm and greater than 4.8mm, use Rockwell hardness tester for pipe, test HR15T hardness. When the inner diameter of a seamless steel pipe is greater than 26mm, you can also use Rockwell or a surface Rockwell hardness tester to test the hardness of the inner wall of the pipe.