Anti-corrosiont nickel based alloy Hastelloy C22 VS C276

Hastelloy alloy has good resistance to pitting corrosion, crevice corrosion and stress corrosion cracking. It was well tolerated for a variety of corrosive medium in oxidation and reduction environments, even as high temperature up to 677 ℃; Hastelloy c-22 and c-276 are the only materials that can resist the corrosion of wet chlorine gas, hypochlorite and chlorine dioxide solution, and offering significant corrosion resistance to high concentration of chloride solution (such as iron chloride and copper chloride).

Hastelloy c-22 and c-276 have excellent welding performance and have been widely used in chemical and petrochemical fields, such as components in contact with chlorinated organics and catalytic systems. They are especially suitable for high temperature, mixed with impurities of inorganic acids and organic acids (such as formic acid and acetic acid), seawater corrosion environment.

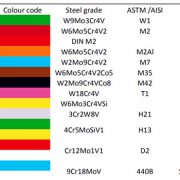

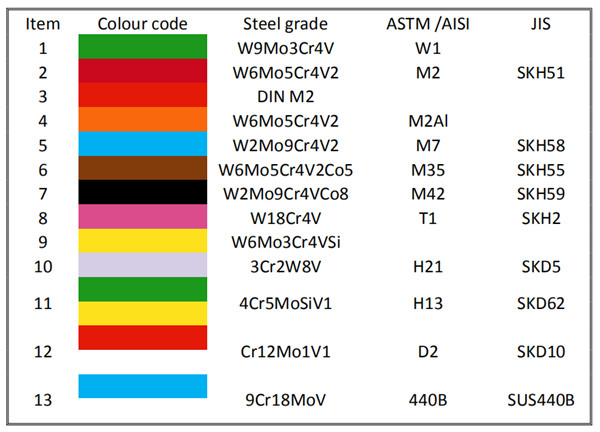

The specification difference from different counties is as follows:

| Chinese | GB/T 15007-2008 | NS3308 | NS334 |

| American | ASTM B462-2006

ASTM B574-2006 ASTM B575-2006 |

N06022 | N10276 |

| Special Metals | INCONEL® alloy 22 | INCONEL® alloy 276 | |

| Haynes International | HASTELLOY® C-22® | HASTELLOY® C-276® | |

| Japanese | JIS H 4551:2000 | NW6022 | NW 0276 |

| Nippon Yakin | NAS NW22 | NAS NW276 | |

| German | DIN 17744:2002 | NiCr21Mo14W

2.4602 |

NiMo16Cr15W

2.4819 |

| VDM Metals | VDM® Alloy 22

Nicrofer® 5621 hMoW |

VDM® Alloy 276

|

The chemical composition (%)difference is as follows:

| Grade | Ni | C | Mo | Cr | Fe | W | Co | Mn | V |

| C22 | 56 | 0.01 | 13 | 22 | 3 | 3 | 2.5 | 0.5 | 0.35 |

| C276 | 57 | 0.01 | 16 | 16 | 5 | 4 | 2.5 | 1 | 0.35 |

We can learn that from the table above, there are few differences in the term of chemical analysis except the content of Mo and Cr. Alloy 22 has a higher Chromium and Molybdenum content than C276, demonstrating improved corrosion resistance in oxidizing aqueous media when high levels of chloride ions are present. In addition, the other differences are:

- Welding material:Varestraint hot-cracking tests performed on commercial alloys revealed a weldability ranking as follows: C-22 > C-276. Intermetallic secondary solidification constituents have been found associated with weld metal hot cracks in Alloys C-276 and C-22(gas-tungsten-arc welds). In Alloy C-276, this constituent is a combination of P and ώ phases, and in Alloy C-22, this constituent is composed of σ, P, and ώ C276 welding materials are wire ernicrmo-4 and electrode enicrmo-4; C22 welding material is wire ERnicrmo-10, electrode Enicrmo-10.

- C22 offers better and more comprehensive corrosion resistance compared with common nickel-chromium-molybdenum alloys such as C-276, C-4 and 625. C22 can be considered as an upgraded version of C276.

- Hastelloy c-22 alloy has a density of 8.7g/cm3, less than that of C276 alloy (8.9). However, C22 is more expensive because the manufacturing cost of C22 is higher than that of C276.

Each alloy has been manufactured to provide a unique set of benefits, wherever it is applied. Both commonly used corrosion resistant alloy. Hastelloy C22 and C276Hastelloy C22 and C276 generally, replace each other in most cases. C276 is more versatile and the C22 offers better performance.

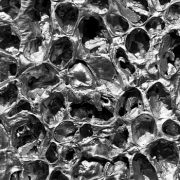

Titanium sponge oxidizes easily. Its large exposed area can absorb a lot of oxygen, the oxidized sponge titanium is impossible to remove oxygen elements in the casting of titanium ingots unlike steel making and only be discarded.

Titanium sponge oxidizes easily. Its large exposed area can absorb a lot of oxygen, the oxidized sponge titanium is impossible to remove oxygen elements in the casting of titanium ingots unlike steel making and only be discarded.